Product Description

Custom CNC Turning Machining Spline Shaft Couplings Steering Shaft Coupler Oldham Coupling

Product Description

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used

as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings. Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction.

Our leading mainly including universal couplings, drum gear couplings, elastic couplings etc.

Main production equipments:

Large lathe, surface grinder, milling machine, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, etc.

| Product Name | Custom CNC Turning Machining Spline Shaft Couplings Steering Shaft Coupler Oldham Coupling |

| Place of Origin | China |

| Certificates | SGS, ISO9001:2008 |

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector etc.

It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer.

FAQ

Q: Why choose Shengao product?

A: We have our own factory, therefore, we can surely promise the quality of product and provide

you competitive price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized machining parts?

A: Yes. Customers give us drawings and specifications, and we will produce accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there’s anything we can help, please feel free to contact with us.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Specific Safety Precautions When Working with Shaft Couplings

Working with shaft couplings involves handling rotating machinery and mechanical components. To ensure the safety of personnel and prevent accidents, specific safety precautions should be followed during installation, maintenance, and operation:

1. Lockout-Tagout (LOTO):

Prior to any work on machinery involving couplings, implement a lockout-tagout procedure to isolate the equipment from its power source. This ensures that the machinery cannot be accidentally energized during maintenance or repair, protecting workers from potential hazards.

2. Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and appropriate clothing, when working with shaft couplings. PPE helps protect against potential hazards such as flying debris, sharp edges, or contact with moving parts.

3. Proper Training and Supervision:

Only trained and authorized personnel should work with shaft couplings. Ensure that workers have the necessary knowledge and experience to handle the equipment safely. Adequate supervision may be required, especially for less-experienced personnel.

4. Inspection and Maintenance:

Regularly inspect shaft couplings and associated components for signs of wear, damage, or misalignment. Address any issues promptly to prevent equipment failure and potential accidents.

5. Follow Manufacturer’s Guidelines:

Adhere to the manufacturer’s instructions and guidelines for installation, operation, and maintenance of the specific coupling model. Improper use or deviation from recommended procedures may compromise safety and void warranties.

6. Avoid Overloading:

Do not exceed the torque and speed limits specified by the coupling manufacturer. Overloading a coupling can lead to premature failure and pose safety risks to operators and nearby equipment.

7. Shaft Guards and Enclosures:

Install appropriate guards and enclosures to prevent accidental contact with rotating shafts and couplings. These safety measures help reduce the risk of entanglement and injuries.

8. Zero Energy State:

Ensure that all stored energy in the equipment, such as compressed air or hydraulic pressure, is released and the equipment is in a zero energy state before starting work.

9. Avoid Loose Clothing and Jewelry:

Remove or secure loose clothing, jewelry, and other items that could get caught in moving parts.

10. Maintain a Clean Work Area:

Keep the work area clean and free from clutter to avoid tripping hazards and facilitate safe movement around the machinery.

By following these safety precautions, personnel can minimize the risks associated with working with shaft couplings and create a safer working environment for everyone involved.

“`

Real-World Examples of Shaft Coupling Applications in Different Industries

Shaft couplings play a crucial role in various industries by connecting rotating shafts and transmitting torque between them. Here are some real-world examples of shaft coupling applications in different industries:

1. Manufacturing Industry:

In manufacturing plants, shaft couplings are used in various equipment such as conveyor systems, pumps, compressors, and mixers. For example, in a conveyor system, shaft couplings connect the motor shaft to the conveyor belt, allowing efficient material handling and transportation.

2. Oil and Gas Industry:

The oil and gas industry utilizes shaft couplings in applications like drilling rigs, pumps, and generators. In drilling rigs, couplings connect the motor to the drill shaft, enabling the drilling process.

3. Marine Industry:

In the marine industry, shaft couplings are found in propulsion systems, water pumps, and winches. They connect the ship’s engine to the propeller shaft, providing the necessary torque for propulsion.

4. Power Generation:

Power plants use shaft couplings in turbines, generators, and cooling systems. For instance, in a steam turbine, couplings connect the turbine to the electrical generator, allowing the conversion of steam energy into electrical power.

5. Aerospace Industry:

Aerospace applications use shaft couplings in aircraft engines, landing gear systems, and auxiliary power units. Couplings enable power transmission between different components of the aircraft systems.

6. Automotive Industry:

In vehicles, shaft couplings are present in the drivetrain, steering systems, and transmission. For example, in a car’s transmission system, couplings connect the engine to the gearbox, enabling smooth gear changes and power transmission to the wheels.

7. Mining Industry:

The mining industry relies on shaft couplings in heavy-duty machinery such as crushers, conveyor belts, and pumps. Couplings connect motors to various mining equipment, facilitating material extraction and transportation.

8. Agriculture:

Agricultural machinery like tractors and harvesters use shaft couplings to connect the engine to implements such as plows, harvesters, and irrigation pumps.

These examples demonstrate the wide-ranging applications of shaft couplings across industries. In each case, the specific coupling type is chosen based on factors such as torque requirements, misalignment compensation, environmental conditions, and load characteristics to ensure reliable and efficient operation.

“`

What is a Shaft Coupling and Its Role in Mechanical Power Transmission?

A shaft coupling is a mechanical device used to connect two shafts together at their ends, allowing for the transmission of mechanical power from one shaft to another. It serves as an essential component in various machinery and industrial applications where rotational motion needs to be transmitted between two shafts that are not perfectly aligned or are separated by a distance.

The role of a shaft coupling in mechanical power transmission includes the following:

1. Power Transmission:

The primary function of a shaft coupling is to transmit power from a driving shaft to a driven shaft. When the driving shaft rotates, the coupling transfers the rotational motion to the driven shaft, enabling the driven equipment to perform its intended function.

2. Misalignment Compensation:

In real-world applications, it is often challenging to achieve perfect alignment between two shafts due to manufacturing tolerances or dynamic conditions. Shaft couplings are designed to accommodate different types of misalignment, such as angular, parallel, and axial misalignment, allowing the equipment to function smoothly even when the shafts are not perfectly aligned.

3. Vibration Damping:

Shaft couplings can help dampen vibrations and shocks caused by uneven loads or sudden changes in the operating conditions. This vibration damping feature protects the connected components from damage and contributes to the overall system’s reliability.

4. Overload Protection:

In some cases, a shaft coupling can act as a safety device by providing overload protection. When the connected machinery experiences excessive torque or shock loads, certain types of couplings can disengage or shear to prevent damage to the equipment.

5. Torque and Speed Conversion:

Shaft couplings can be designed to provide torque and speed conversion between the driving and driven shafts. This allows for adaptation to different operating conditions and varying torque requirements in the connected machinery.

6. Flexible Connection:

Shaft couplings with flexible elements, such as elastomeric inserts or flexible discs, provide a flexible connection that can absorb shocks and misalignments. This flexibility helps reduce stress on the connected equipment and extends its lifespan.

Overall, shaft couplings are essential components in mechanical power transmission systems, enabling the efficient transfer of rotational motion between shafts while accommodating misalignments and providing protection against overloads and vibrations. The selection of the appropriate coupling type and design depends on the specific requirements of the application, including the type of misalignment, torque capacity, and operating conditions.

“`

editor by CX 2024-02-21

China high quality OEM CNC Machining Split Motor Rigid Shaft Coupling

Product Description

OEM CNC Machining Split Motor Rigid Shaft Coupling

|

Customized cnc machining parts notes: |

||||

|

Quotation |

According to your drawing(size, material, thickness, processing content, and required technology, etc) |

|||

|

Tolerance Surface Roughness |

+/-0.02 – 0.01mm Ra0.2 – Ra3.2(Customized avaiable) |

|||

|

Materials Avaiable |

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, etc. |

|||

|

Surface Treatment |

Polishing, general/hard/color oxidation, surface chamfering, tempering, etc. |

|||

|

Processing |

CNC Turning, Milling parts, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

|||

|

Testing Equipment |

CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement |

|||

|

Drawing Formats |

PRO/E, Auto CAD, CZPT Works , UG, CAD / CAM / CAE, PDF PRO/E, Auto CAD, CZPT Works , UG, CAD / CAM / CAE, PDF |

|||

|

Our Advantages |

(1) 24 hours online service & Quickly Quote/Delivery. (2) 100% QC quality inspection before delivery, and can provide quality inspection form. |

|||

Features of jaw coupling:

1.Easy of inspection,easy maintenance.

2.Can absorb vibration,parallel,angular and axial misalignments.

3.Identical clockwise and anticlockwise rotational charateristics.

4.Both ends material is iron, intermediate for rubber materials.

5.Simple configuration, setscrew type,low price.

6.Hole can be self-processing,easy facilitate.

7.For step motor,screw, machine positioning system.

The SL cross slide coupling is slid in the corresponding radial grooves of the large end faces

of the half couplings on both sides.

The main feature of the slider coupling is that it allows the 2 shafts to have a large radial

displacement, and allows for small angular displacement and axial displacement. Due to the

centrifugal force generated by the eccentric motion of the slider, it is not suitable to use this

coupling. High-speed movement, the coupling torque of the coupling is 120-63000N.m, the

speed is 250-70r/min.

Advantages:

Protects driven component by serving as a mechanical “fuse” – an inexpensive replaceable plastic

midsection shears under excess load.

Protects support bearings by exerting consistently low reactive forces, even under large misalignments.

Homokinetic transmission – driving and driven shafts rotate at exactly the same speed at all times.

Zero backlash and high torsional stiffness.

Accommodates large radial misalignment in a short length.

Easy installation in blind or difficult installations when through-bores are used.

Economically priced compared to other couplings with similar performance characteristics.

CNC machining parts, metal machining parts, precision machining parts, Machined parts, Machinery

parts,Machine Parts,machining parts machining,Cnc machining parts machinery parts,machined

parts,precision machining parts,oem machining parts,cnc machining parts,cnc machined parts.

Q: Why choose Shengao product?

A: We shengao have our own plant– HangZhou Shengao machinery Co.,Ltd, therefore, we can

surely promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized machining parts?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there’s anything we can help, please feel free to contact with us.

How to Properly Install a Rigid Shaft Coupling for Optimal Performance and Reliability

Proper installation of a rigid shaft coupling is essential to ensure optimal performance and reliability in mechanical systems. Here are the steps to follow for a successful installation:

- Shaft Preparation: Ensure that the shafts to be connected are clean, smooth, and free from any burrs or contaminants that could affect the coupling’s performance.

- Alignment: Align the two shafts accurately to minimize misalignment during installation. The alignment process is critical as any misalignment can lead to premature wear and reduced coupling efficiency.

- Fitment: Choose the appropriate size of the rigid shaft coupling that matches the shaft diameters. Carefully slide the coupling onto one shaft at a time.

- Fastening: For one-piece rigid couplings, ensure that the coupling is fitted snugly onto both shafts. For two-piece couplings, bolt the two halves together securely around the shafts.

- Tightening: Use the recommended torque value and follow the manufacturer’s guidelines to tighten the coupling bolts properly. Over-tightening can cause distortion, while under-tightening can lead to slippage and reduced torque transmission.

- Inspection: After installation, inspect the coupling to ensure that it is centered and aligned correctly. Check for any signs of misalignment or interference during rotation.

- Lubrication: Some rigid couplings may require lubrication at the friction points to reduce wear and friction. Follow the manufacturer’s recommendations for lubrication intervals and types.

- Load Testing: Perform load testing on the system to verify the coupling’s performance and check for any unusual vibrations or noises during operation.

- Regular Maintenance: Include the rigid coupling in your regular maintenance schedule. Periodically check for signs of wear, misalignment, or damage, and replace the coupling if necessary.

By following these installation steps and best practices, you can ensure that the rigid shaft coupling operates optimally, providing reliable torque transmission and contributing to the overall efficiency and longevity of the mechanical system.

Are there any real-world case studies or success stories of using rigid shaft couplings in various engineering projects?

While specific case studies might not be readily available, there are numerous real-world examples of using rigid shaft couplings in various engineering projects across industries. These projects highlight the versatility and benefits of rigid shaft couplings in different applications:

- Industrial Machinery: Rigid shaft couplings are commonly used in industrial machinery such as conveyor systems, pumps, compressors, and machine tools. They ensure precise torque transmission, alignment, and stability in these critical applications, contributing to reliable and efficient operation.

- Robotics: Robotics often require accurate and repeatable motion control. Rigid couplings provide a rigid connection between robotic joints and actuators, ensuring precise movement and positioning.

- Aerospace: In aerospace applications, where safety and reliability are paramount, rigid shaft couplings play a role in connecting various components, such as engine components and control surfaces, ensuring consistent and reliable performance.

- Medical Equipment: Rigid couplings are used in medical devices such as diagnostic equipment, laboratory instruments, and surgical tools. They contribute to accurate motion control and sample manipulation.

- Automotive: Rigid shaft couplings can be found in automotive systems, including drivetrains and transmission systems. They ensure efficient torque transmission and alignment in components such as steering columns.

- Printing and Packaging: Printing presses and packaging machinery rely on rigid couplings to maintain precise alignment between rollers and components, ensuring consistent print quality and packaging accuracy.

While these examples illustrate the broad range of applications where rigid shaft couplings are used, it’s important to note that the success of each project is influenced by factors beyond just the coupling. Proper installation, maintenance, and integration into the overall system are crucial for achieving optimal results.

When considering the implementation of rigid shaft couplings in a project, engineers should collaborate with coupling manufacturers, suppliers, and experienced professionals to ensure proper selection, installation, and operation. By leveraging the advantages of rigid couplings, engineering projects can benefit from improved efficiency, reliability, and performance.

Are There Different Types of Rigid Shaft Couplings Available, and What Are Their Specific Applications?

Yes, there are different types of rigid shaft couplings available, each with its own specific applications. Some common types of rigid shaft couplings include:

- Sleeve Couplings: Sleeve couplings are simple and cost-effective couplings that connect two shafts together using a solid sleeve or tube. They are commonly used in applications with moderate torque requirements and where shaft alignment can be maintained with high precision.

- Clamp or Split Couplings: Clamp or split couplings consist of two halves that are clamped together around the shafts using screws or bolts. They are easy to install and suitable for applications where frequent maintenance or disassembly is required.

- Flanged Couplings: Flanged couplings have flanges on both ends that are bolted together. They are used in applications where shafts need to be rigidly connected and where some degree of axial movement is expected.

- Tapered Shaft Couplings: Tapered shaft couplings have tapered bores that fit tightly onto tapered shafts, creating a friction-based connection. They are often used in applications where precise alignment and torque transmission are essential.

- Keyed Shaft Couplings: Keyed shaft couplings use a key and keyway arrangement to connect the shafts securely. They are commonly used in heavy-duty applications where high torque transmission is required.

The choice of rigid shaft coupling depends on the specific requirements of the application. Factors such as torque transmission, shaft size, alignment precision, ease of installation, and maintenance needs play a crucial role in selecting the appropriate coupling type.

Rigid shaft couplings are widely used in various industries, including manufacturing, power generation, robotics, aerospace, and automotive. They are often employed in applications such as pumps, compressors, conveyors, and high-precision machinery.

It is essential to consider the specific demands of the application and consult with coupling manufacturers or experts to determine the most suitable rigid coupling type for optimal performance and reliability.

editor by CX 2023-08-17

China OEM Precision CNC Machining Flexible Jaw Sliding Coupling coupling chemistry

Solution Description

OEM Precision CNC Machining Versatile Jaw Sliding Coupling

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| three). Steel: 4140, Q235, Q345B,twenty#,45# etc. | |

| four). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| five). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| six). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | Stage,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-.01mm ~ +/-.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1571mm*500mm |

Features of jaw coupling:

1.Simple of inspection,easy servicing.

2.Can soak up vibration,parallel,angular and axial misalignments.

3.Similar clockwise and anticlockwise rotational charateristics.

4.Both finishes material is iron, intermediate for rubber resources.

5.Straightforward configuration, setscrew kind,minimal price.

6.Gap can be self-processing,easy facilitate.

7.For step motor,screw, equipment positioning system.

The SL cross slide coupling is slid in the corresponding radial grooves of the huge finish faces

of the 50 percent couplings on both sides.

The principal function of the slider coupling is that it allows the 2 shafts to have a big radial

displacement, and permits for small angular displacement and axial displacement. Due to the

centrifugal pressure produced by the eccentric movement of the slider, it is not suitable to use this

coupling. High-velocity movement, the coupling torque of the coupling is one hundred twenty-63000N.m, the

speed is 250-70r/min.

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )

Advantages:

Protects driven ingredient by serving as a mechanical “fuse” – an inexpensive replaceable plastic

midsection shears under surplus load.

Protects assist bearings by exerting regularly lower reactive forces, even beneath massive misalignments.

Homokinetic transmission – driving and pushed shafts rotate at specifically the exact same velocity at all times.

Zero backlash and large torsional stiffness.

Accommodates big radial misalignment in a brief duration.

Easy installation in blind or hard installations when by means of-bores are used.

Economically priced in comparison to other couplings with similar performance attributes.

CNC machining parts, metal machining parts, precision machining parts, Machined parts, Machinery

parts,Machine Parts,machining parts machining,Cnc machining parts machinery parts,machined

parts,precision machining parts,oem machining parts,cnc machining parts,cnc machined parts.

Q: Why choose Shengao product?

A: We shengao have our own plant– HangZhou Shengao machinery Co.,Ltd, therefore, we can

surely promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized machining components?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there’s anything we can help, please feel free to contact with us.

|

US $10 / Piece | |

1,000 Pieces (Min. Order) |

###

| After-sales Service: | as Specification |

|---|---|

| Warranty: | 6 Months |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |

|

US $10 / Piece | |

1,000 Pieces (Min. Order) |

###

| After-sales Service: | as Specification |

|---|---|

| Warranty: | 6 Months |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |

What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by czh 2023-01-01

in Sofia Bulgaria sales price shop near me near me shop factory supplier Custom CNC Machining Auto Transmission Spline Shaft Parts High Precise Manufacturers Factory Custom Precision Lathing Milling Grinding CNC Machined manufacturer best Cost Custom Cheap wholesaler

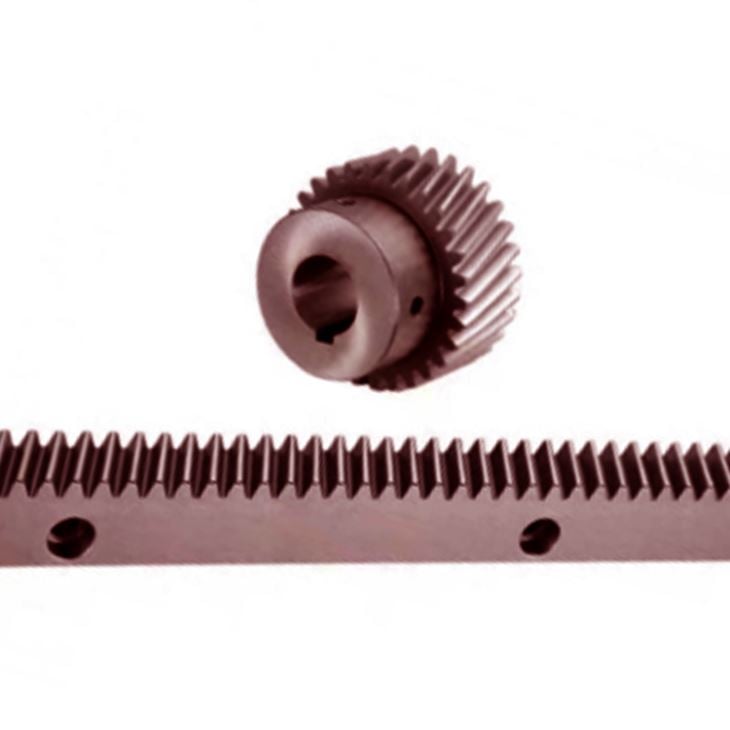

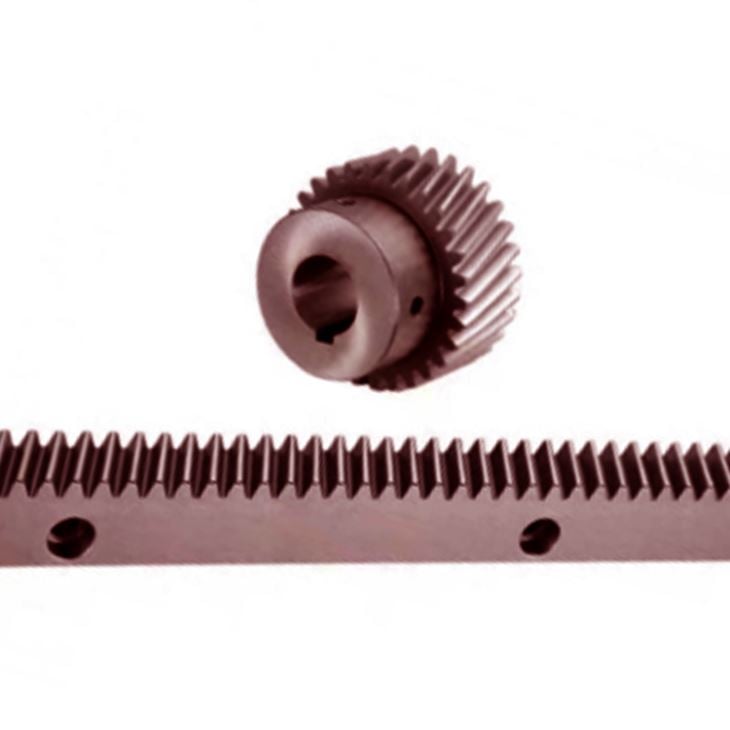

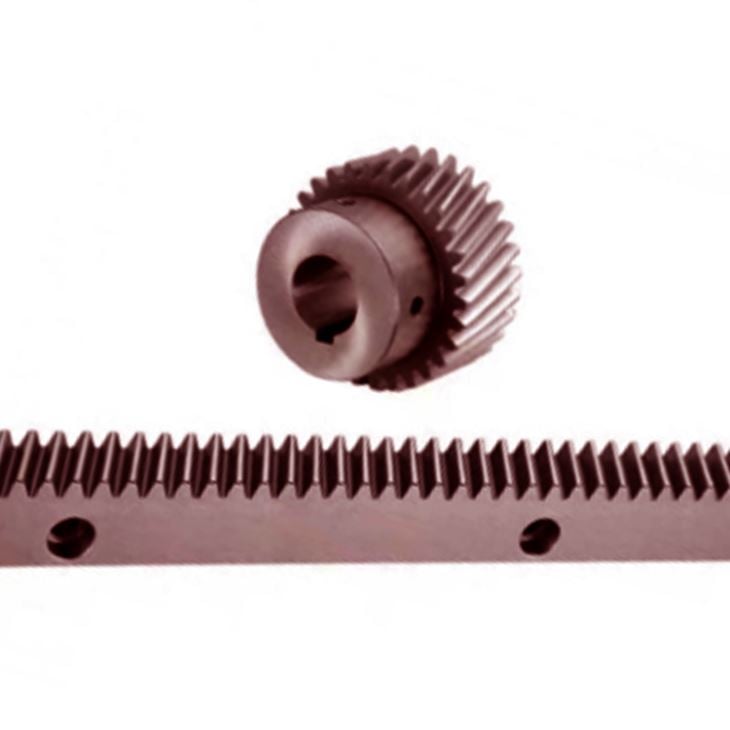

Due to our extensive solution assortment and prosperous encounters in this sector, We can supply a total-range of power transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. If you are interested in any of our products or would like to examine a possible buy, make sure you feel free of charge to speak to us.

| Product Description | |

| Merchandise Identify | Steering knuckle for for car/autos/EPT/trailer |

| EPT | Gray Iron, Ductile Iron,alluminul alloy,etc |

| The casting tactics | Low force casting,Gravity casting,Sand casting, lost foam casting/EPTC casting, shell mold casting |

| Our creation ability | one thousand-2000 tons / for every month. |

| The weigEPTT for castings | .80kgs – 1000kgs. |

| Machining | Turning, cutting, milling, grinding, drilling, reaming and threading. |

| Tolerance for machining | .01mm-.03mm |

| EPT | Lathe, planer, drilling EPTT, tapping EPTT, line chopping, milling EPTT, CNC machining cEPTTr. |

| Floor Treatment | Shot blast, portray, chrome plating, EPTT coating,and so on |

| Specification | In accordance to customers’ drawing, specification and / or samples |

| Our associate | BYD,EPT,Honda,GAIC Group ,SAIC group, BAIC group,Broad-EPTT,AKEI,Inovance, EPTTeEPT,and many others |

in Dnipro Ukraine sales price shop near me near me shop factory supplier Years-Experience OEM Supplier Various Casting CNC Machining Parts manufacturer best Cost Custom Cheap wholesaler

We are aiming to satisfy the calls for of the clients around the planet.. we have received the have confidence in of consumers globally. Every single procedure, every single part, each purpose in EPG is demanded to be carried out one stage following yet another, very carefully and cautiously, from materials variety, reformation to producing accessories, from parts warmth remedy to computerized assembly, from top quality manage to merchandise inspection and tests and from get dealing to right after product sales service. Item Description

| EPT | EPTT: AL6061, Al6063, AL6082, AL7075, AL5052, AL2571 |

| Stainless steel: SS201, SS301, SS303, SS304, SS316, SS430 etc | |

| Steel: delicate metal/ carbon steel incXiHu (West EPT) Dis.Hu (West EPT) Dis. 1571, 1571, 1045, 1050, Q690 and so on | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 and so on. | |

| Copper: C11000, C12000, C12000, C17200, C72900, C36000 etc. | |

| Processing EPT |

Germany Trumpf brand name Laser cutter, CNC shearing EPTT, CNC bending EPTT, |

| (CNC) stamping EPTT, Hyraulic EPTT, A variety of welding EPTT, CNC EPTT cEPTTr. |

|

| Surface Treatment method |

EPTT: Anodization, Sandblast, Brushing, PoEPTTng, Electro-plating and so forth |

| Stainless Metal: PoEPTTng, Brushing, Passivating, Sandblasting, Electro-plating | |

| Steel: Zinc plating, Nickel plating, Chrome plating, PowEPTTCoating, Portray and many others | |

| Brass amp Copper: Brushing, PoEPTTng and so forth | |

| EPT | – .002mm |

| Software | Railway, Automobile, EPT, Health-related, EPTTry, EPT, EPT, EPT and so on |

Why Pick Us

EPTTngdao EPT EPTTry EPTT, Ltd. is positioned in EPTTngdao metropolis with convenient transportation to EPTTngdao sea port and EPTTngdao airport.

We are a specialist provider, engaged in the engineering, deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment,producing, sale and service of EPT CNC machining elements, sheet steel amp stamping areas, casting areas, plastic EPT molding parts for numerous EPTT, and are dedicated to providing one-cease resolution for EPT areas.

Our products are exported to North The us, Europe, EPTTia, Asia and other countries and regions. We purpose to constantly set the stringent stXiHu (West EPT) Dis.Hu (West EPT) Dis.rds of consumer gratification in our sector, we will be far more constructive perspective, do a very good work, wonderful service for every single customer.

We feel it will be a good decision for you. Contacting us now, we assure that you will not likely be unhappy.

There are CNC machining cEPTTr, Gantry machining cEPTTr,CNC turning, Drilling, Laser Chopping, CNC Bending, CNC Punching, welding and many others EPTT in our workshop. EPT we could method is steel, stainless metal, iron, EPT, zinc, magnesium, copper, plastic, rubber and so forth.

There are CMM, Projector, tough meter, roundness measuring instrument, micrometer, caliper and so forth. inspection instrument and gadgets.

Committed to rigid quality handle and thoughtful customer services, our knowledgeable employees customers are alwaEPTTavailable to discuss your requirements and ensure full customer satisfaction.

In addition, we have received ISO9001 administration certificate. Our company attaches EPTTance to the effect of deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment on the environment, EPT has a EPTT of knowledge in the precise fabrication of EPT metal amp plastic areas, with EPT-efficient, useful, productive manufacturing to satisfy the prerequisite of our client.

FAQ

1. Could you offer samples?

Of course, we can.

2. What is the MOQ?

A single piece is suitable.

three. What is your manufacturing lead time?

Usually fifteen daEPTTto 30 daEPTTdepending the PO quantity.

four. How to get a quotation?

You should deliver us the element drawings, and allow us know the asked for substance, annual use and weight for quotation.

5. What is your payment phrase?

L/C, D/A, D/P, T/T, Western EPT, MoneyGram, Paypal.

Make contact with EPT

Annie Li

EPT Manager

EPTTngdao EPT EPTTry EPTT, Ltd

Include: No.29, RuiEPTT Road, XiHu (West EPT) Dis.hu (West EPT) Dis. District, EPTTngdao, ZheJiang , EPTT (Mainland)

Web site:

in Karbala Iraq sales price shop near me near me shop factory supplier High Reliability Precision CNC Machining Sliding Multi-Diameter Spline Shaft for Aisin manufacturer best Cost Custom Cheap wholesaler

With comprehensive requirments, we can also build your special made solution. Fantastic interest has been compensated on environmental protection and energy preserving. In addition, all our creation procedures are in compliance with ISO9002 standards.

| Utilization | For new power motor vehicle electrical EPT shaft/EPT motor shaft/EPT rotation shaft/EPT spline shaft/EPT shaft/EPT shaft,etc |

| Specification | Duration:100-500mm,Outdoors Dia.:twenty-90mm,Spline module:.eight-3 or EPTT |

| Area Treament | Anodizing/ OXiHu (West EPT) Dis.ding/ Zinc plating/ Nickel plating/ Chrome plating/ Silver plating/ EPT plating/ Imitation EPT plating/ Sand blasted/ Brushed/ Silk EPT/ Passivation/ EPTT coating/ Portray/ Alodine/ Heat treatment method/ Teflon etc. |

| Tolerance | /-.005mm or /- .0002 |

| EPT | Stainless Steel,EPTT Steel We manage several other variety of components. Please make contact with us if your necessary materials is not detailed previously mentioned. |

| Inspecation EPT | Coordinate measuring machining/ Projector/ Caliper/ EPTscope/ EPTmeter/ EPT gauge/ Roughness tester/ Gauge block/ Thread gauge and so on. |

| EPTT EPTT | 100% inspection |

| EPTT | Yes,all are EPT according clients’ drawings design and style or sample |

| Our Consumer | BYD,EPT,Honda,GAIC Team ,SAIC group, BAIC group,Broad-EPTT,AKEI,Inovance, EPTTeEPT,and so forth |

Best China manufacturer & factory China in Singapore Singapore manufacturer Manufacturer high precision cnc machining metal steel out ring and pinion gears With high quality best price

EPG has set up a complete established of high quality management system which is offered with innovative inspection and check tools.

Overview

Rapid Details

- Applicable Industries:

-

Building Materials Shops, Production Plant, Machinery Fix Shops, Foods & Beverage Manufacturing facility, farms, Strength & Mining

- Other Region:

-

TianJin,China

- Item Title:

-

Ring gear

- Application:

-

Production Plant

- processing:

-

Precision

- Normal:

-

Common/customized

- Coloration:

-

Character

- Teeth variety:

-

spur

- Strain angle:

-

twenty diploma

- Bundle:

-

Carton

- Module:

-

M1-M6/tailored

Source Ability

- Provide Potential:

- 5000 Piece/Pieces for every Day

Packaging & Shipping and delivery

- Packaging Information

- plastic baggage +cartons+wodden situation

- Port

- TIANJIN PORT/SHANGHAI PORT/QINGDAO PORT

-

Direct Time

: -

“EPG” brand rotocultivator ploughshares in T.S. whole traces created in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China.

Quantity(Bags) 1 – a hundred one zero one – a thousand >1000 Est. Time(days) seven 15 To be negotiated

On the internet Customization

To deal with these sealing and effectiveness concerns, Emerson Energy Transmission (EPT) developed numerous layout and producing tips. The resulting gearboxes have a tendency to operate cooler and leak cost-free, when compared with typical worm gear models.

EPG offer you widest selection of gearbox and pace reducers, conveyor chains and transmission components like equipment, sprocket, racks, pulley, shaves and taper bushes and so on for a variety of applications

Merchandise Description

|

Merchandise name |

Ring equipment |

||||||

|

Warmth therapy |

Quenching,carburizing,substantial frequency hardening,carbonitriding |

||||||

|

Processing |

Hobbing , milling , shaping , grinding , shaving , lapping,ect. |

||||||

|

Substance |

C45/stainless metal/brass/plastic/nylon,ect |

||||||

|

Surface area treatment |

Blacking,sprucing,anodization/chrome plating,zic plate,ect |

||||||

Diverse sort gear

worm equipment

helical equipment

spur equipment

bevel gear

equipment shaft

spiral bevel gear

Different content

brass equipment

C45/42CR equipment

plastic equipment/nylon/pom

stainless metal

Software

Payment

Packing & Shipping

Principal solution

roller chain

equipment

timing pulley

equipment rack

linear rail and block

ball screw

Company profile

HangZhou EPG – The most significant transmission components manufacuturer in China Electrical Gear Co.,Ltd was launched in HangZhou in 2008 and is a specialist maker and exporter that is involved with the design, advancement and generation.With thorough requirments, we can also produce your special developed item. Our solution assortment involves all varieties of helical gear, spur equipment, bevel equipment, gear rack, worm equipment, sprockets,chains,bearings.Keeping in mind that good services is the essential to cooperating with consumers, we strive to meet up with substantial good quality requirements, supply competitive prices and guarantee prompt delivery. In this way, our goods have ongoing to obtain marketWe made, specifically for our customers, a protective cone which is versatile and enables less difficult dealing with even though coupling the PTO on the tractor or functioning device. The flexible cone provides further ease and comfort when coupling the PTO, since you can get a great grip in the restricted shaft room. acceptance and clients gratification above the earlier couple of many years. We are aiming to fulfill the requires of the clients close to the planet..If you are fascinated in any of our items or would like to examine a likely order, make sure you come to feel free of charge to make contact with us. We are hunting forward to creating successful organization relationships with new consumers around the globe in the foreseeable future.

Best China manufacturer & factory Custom Precision cnc machining price cnc milling machining parts With high quality best price

Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.

30 To be negotiatCast Iron Gearbox: After Painting with Red Antirust Paint, Paint with the Color of RAL 5010 Gentian Blue Models: Hollow Shaft Input with IEC-normalized Motor Flange ed

Online Customization

Custom Precision cnc machining price cnc milling machining parts

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,PEPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association. lating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

More service

More Production Part

Surface Treatment

Production Process

Why Us

Best China manufacturer & factory CNC machining pinion gear made by POM ABS Nylon PTFE PEEK etc With high quality best price

The product well displays environmental protection and energy saving.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Teeth Type:

-

If you’re looking for a 540 PTO shaft, 540 to 1000 PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no further. It’s important to replace PTO parts that are worn or cracking before you have a major breakdown that could be expensive and even dangerous. We have PTO drive shafts as well as essential shield parts for your safety. Our Eurocardan parts include a range of types of clutches to improve the operation of your power take-off system. PTO shafts and accessories are an important part of the more than 26,000 items we carry for farm, shop, home and garden.

Spur or Helical

- Module:

-

0.2-20

- Normal material:

-

POM, Nylon, ABS, PTFE, PEEK

- MOQ:

-

1pc

- Service:

-

Reply in 12 hours at any time

- Worm gearboxes are noted for reliable power transmission. Computer-aided assembly of the Morse Raider gearbox eliminates effects of cumulative manufacturing tolerances and helps maximize operating efficiency. The unit also features a redesigned breather and textured shaft surface, letting the manufacturer offer an 18-month leak-free guarantee. An automatic centering machine measures gearbox components and guides assembly to maximize operating efficiency. Color:

-

White, Black, Blue Green etc.

- Technic:

-

Machining or Inject

Supply Ability

- Supply Ability:

- 50000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- carton box

- Port

- Ningbo, Shanghai or as request

-

Lead Time

: -

Quantity(Bags) 1 – 200 201 – 1000 1001 – 5000 >5000 Est. Time(days) 10 15 20 To be negotiated

Online Customization

It is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement.

CNC machining pinion gear made by POM ABS Nylon PTFE PEEK etc

Product Description

|

Facilities |

Machining center; |

||||||

|

Gear types |

Helical gears (more and more widely used for its stable transimission); |

||||||

|

Material |

PA6, PA66, POM, ABS Nylon, Plastic, PTFE, PEEK, PP, PS, PC etc. |

||||||

|

Technic |

Machining for small quantity, injection for large quantity. |

||||||

|

More material |

Steel, Stainless steel, Copper, Aluminium, Aluminum alloy etc. |

||||||

The producing character of JH gears:

1. Gear size: the biggest diameter is 500mm;

2. Gear module: 0.2-8 (pitch from 0.942-25.12mm, DP 3.175-85);

3. Quality: stable and high, grade 7 for without teeth grinding, grade 6 after teeth grinding, grade 5 for precise grinding.

Prices for above quality are very competitive for us.

The quality character of JH gears:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The teeth can be ground to grade 6 and grade 5 quality;

4. The bore will be polished to smooth and high precision;

5. The price is competitive even the quality is high.

Detailed Images

Related product

Company Profie

SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, ARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACUUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS

ACCORDING TO CUSTOMERS’ DRAWINGS.

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Packing & Delivery

Why Choose Us

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies, Kuhn

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-> Our Company with over twelve year’s history and 1000 workers and 20 sales.

-> With over 100 Million USD sales in 2017

-> With advance machinery equipments

-> With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

For more detail, please contact us.

Custom supplier China in Vereeniging South Africa Made Precision CNC Machining Crankshaft Pulley for Power Transmission Parts with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Custom made precision cnc machining crankshaft pulley for power transmission parts

Surface: As your requirement

Material: Steel / aluminum / brass / iron / zinc / alloy

Any EPT material and dimension depends on customers’ demand.

Usage: EPT / furniture / toy / woodboard / wall

EPT process: Stamping parts

Euipment: CNC Machining machine

Testing equipment: Projector

Industry Focus Appliance/ Automotive/ Agricultural Electronics/ Industrial/ EPT Mining/ Hydraulics/ Valves Oil and Gas/ Electrical/ Construction

Industry Standards ISO 9001: 2008 PPAP Ro EPT Compliant

Additional Capabilities C EPT Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering

| Specification | custom made |

| Our features | 1. 14 years history 2. Short lead time 3.Good after-sale service 4. Free samples provided |

| Material | Stainless steel, copper, brass, carbon steel, aluminum (according to customer’s requirement. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Main Products | Precision screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping parts,washer,gasket, plastic molding injection parts, standoff,CNC machining service,accessories etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Available Certificate | RoHS, SGS, Material Certification |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual,It will based on the detailed order quantity. |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Delivery of Samples | By DHL,Fedex,UPS, TNT,EMS^^ |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! | |

| Applications | Toy,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market/ hotel equipment supplies, artware etc. |

EPT parts for your look,

Company Information

HK AA Industrial Co,. Limited, is located in NO 4 Building, Jinlong Industrial Zone Xihu (We EPT Lake) Dis. Road, Xiekeng, Qingxi, HangZhou, ZheJiang province, China. HK AA was founded in 1998, covering an area of 11,000 square meters and 200 workers . 90% of our products are sold to overseas market such as USA, Canada, Germany, UK, Italy, Australia, Japan, South Korea etc. We are ISO 9001:2008, ISO13485 (medical)and TS16949(automotive) certified company. We will have AS9100 certificate(aerospace) In 2018.

Certification

FAQ

Q1: How to guarantee the Quality of Industrial Parts?

A1: we are ISO 9001-2008 certified firm. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What’s the Advantage of Your Parts for Industry Products?

A2: Our advantage is the competitive prices, fa EPT delivery and high quality. Our employees are responsible-oriented, friendly-oriented, and dilient-oriented. our Industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipmengts?

A3: Our machining equipments include CNC milling machines, CNC turning machines, stamping

machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines,

screw machines, cutting machines and so on.

Q4: What shipping ways our use?

A4: Generally speaking, we will use UPS or DHL to ship the products. Our customers can reach the

products within 3 days. If our customers do not need them urgently, we will also use FedEx and TNT. If the products are of heavy weight and large volumn, we will ship them by sea. This way can save

our customers a lot of money.

Q5: Who are our main customers?

A5: HP, Samsung, Jabil Group, Lexmark, Flextronic Group.

Q6: What materia EPT can you handle?

A6: Brass, bronze, copper, stainless steel, steel, aluminum, titanium And plastic.

Q7: How Long is the Delivery for Your Industrial Part?

A7: Generally speaking, it will take us 15 working days for machining parts and 25 working days for

the for stamping parts products. But we will shorten our lead time according to customers’ demands

if we are able to.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.