Product Description

SC Transmission FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

FCL Coupling/Shaft Coupling /Pin & Bush Coupling /FCL Flexible Coupling/NBK FCL Coupling is widely used for its compacts designing, easy installation, convenient maintenance, small and light weight.

As long as the relative displacement between shafts is kept within the specified tolerance, couplings will operate the best function and have a longer working life.

Thus it is greatly demanded in medium and minor power transmission systems driven by motors, such as speed reducers, hoists, compressors, conveyors, spinning and weaving machines and ball mills.

Product Parameters

| SIZE | D | D1 | d1 | L | C | n-M | kg | |||

| r/min | ||||||||||

| N.m | ||||||||||

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

Company Profile

FAQ

Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How to Select the Right Shaft Coupling for Specific Torque and Speed Requirements

Selecting the appropriate shaft coupling involves considering the specific torque and speed requirements of the application. Here’s a step-by-step guide to help you choose the right coupling:

1. Determine Torque and Speed:

Identify the torque and speed requirements of the application. Torque is the rotational force required to transmit power between the shafts, usually measured in Nm (Newton-meters) or lb-ft (pound-feet). Speed refers to the rotational speed of the shafts, typically measured in RPM (revolutions per minute).

2. Calculate Torque Capacity:

Check the torque capacity of various shaft couplings. Manufacturers provide torque ratings for each coupling type and size. Ensure that the selected coupling has a torque capacity that exceeds the application’s torque requirements.

3. Consider Misalignment:

If the application involves significant shaft misalignment due to thermal expansion, vibration, or other factors, consider flexible couplings with good misalignment compensation capabilities. Elastomeric or beam couplings are popular choices for such applications.

4. Assess Operating Speed:

For high-speed applications, choose couplings with high rotational speed ratings to avoid resonance issues and potential coupling failure. High-speed couplings may have specialized designs, such as disk or diaphragm couplings.

5. Evaluate Environmental Conditions:

If the coupling will operate in harsh environments with exposure to chemicals, moisture, or extreme temperatures, select couplings made from corrosion-resistant materials or with protective coatings.

6. Check Torsional Stiffness:

In applications requiring precision motion control, consider couplings with high torsional stiffness to minimize torsional backlash and maintain accurate positioning. Bellows or Oldham couplings are examples of couplings with low torsional backlash.

7. Size and Space Constraints:

Ensure that the selected coupling fits within the available space and aligns with the shaft dimensions. Be mindful of any installation limitations, especially in confined spaces or applications with limited radial clearance.

8. Consult Manufacturer’s Data:

Refer to the manufacturer’s catalogs and technical data sheets for detailed information on each coupling’s torque and speed ratings, misalignment capabilities, materials, and other relevant specifications.

9. Consider Cost and Maintenance:

Compare the costs and maintenance requirements of different couplings. While some couplings may have higher upfront costs, they could offer longer service life and reduced maintenance costs in the long run.

By following these steps and considering the specific torque and speed requirements of your application, you can select the right shaft coupling that will ensure efficient power transmission and reliable performance for your mechanical system.

“`

Temperature and Speed Limits for Different Shaft Coupling Types

The temperature and speed limits of shaft couplings vary depending on the materials and design of the coupling. Manufacturers provide specific guidelines and ratings for each coupling type. Below are general temperature and speed limits for some common shaft coupling types:

1. Elastomeric Couplings:

Elastomeric couplings, such as jaw couplings and tire couplings, typically have temperature limits ranging from -40°C to 100°C (-40°F to 212°F). The speed limits for elastomeric couplings are generally up to 5,000 RPM, but some designs may allow higher speeds.

2. Metallic Couplings:

Metallic couplings, like gear couplings and disc couplings, can handle a wider temperature range, typically from -50°C to 200°C (-58°F to 392°F). The speed limits for metallic couplings vary based on the size and design, but they can range from 3,000 RPM to over 10,000 RPM.

3. Grid Couplings:

Grid couplings have temperature limits similar to metallic couplings, ranging from -50°C to 200°C (-58°F to 392°F). The speed limits for grid couplings are typically in the range of 3,000 to 5,000 RPM.

4. Oldham Couplings:

Oldham couplings usually have temperature limits from -30°C to 100°C (-22°F to 212°F) and speed limits ranging from 1,000 to 5,000 RPM.

5. Beam Couplings:

Beam couplings generally have temperature limits from -40°C to 120°C (-40°F to 248°F) and speed limits between 5,000 to 10,000 RPM.

6. Fluid Couplings:

Fluid couplings are suitable for a wide range of temperatures, often from -50°C to 300°C (-58°F to 572°F). The speed limits depend on the size and design of the fluid coupling but can extend to several thousand RPM.

It’s important to note that these are general guidelines, and the actual temperature and speed limits may vary based on the specific coupling manufacturer, material quality, and application requirements. Always refer to the manufacturer’s documentation and technical specifications for accurate and up-to-date temperature and speed limits for a particular shaft coupling model.

“`

Diagnosing and Fixing Common Issues with Shaft Couplings

Regular inspection and maintenance of shaft couplings are essential to detect and address common issues that may arise during operation. Here are steps to diagnose and fix some common coupling problems:

1. Abnormal Noise or Vibration:

If you notice unusual noise or excessive vibration during equipment operation, it may indicate misalignment, wear, or damage in the coupling. Check for any visible signs of damage, such as cracks or deformations, and inspect the coupling for proper alignment.

Diagnosis:

Use a vibration analysis tool to measure the vibration levels and identify the frequency of the abnormal vibrations. This can help pinpoint the source of the problem.

Fix:

If misalignment is the cause, adjust the coupling to achieve proper alignment between the shafts. Replace any damaged or worn coupling components, such as spiders or elastomeric inserts, as needed.

2. Excessive Heat:

Feeling excessive heat on the coupling during operation can indicate friction, improper lubrication, or overload conditions.

Diagnosis:

Inspect the coupling and surrounding components for signs of rubbing, lack of lubrication, or overloading.

Fix:

Ensure proper lubrication of the coupling, and check for any interference between the coupling and adjacent parts. Address any overloading issues by adjusting the equipment load or using a coupling with a higher torque capacity.

3. Shaft Movement:

If you observe axial or radial movement in the connected shafts, it may indicate wear or improper installation of the coupling.

Diagnosis:

Check the coupling’s set screws, keyways, or other fastening methods to ensure they are secure and not causing the shaft movement.

Fix:

If the coupling is worn or damaged, replace it with a new one. Ensure proper installation and use appropriate fastening methods to secure the coupling to the shafts.

4. Sheared Shear Pin:

In shear pin couplings, a sheared shear pin indicates overloading or shock loads that exceeded the coupling’s torque capacity.

Diagnosis:

Inspect the shear pin for damage or breakage.

Fix:

Replace the sheared shear pin with a new one of the correct specifications. Address any overloading issues or adjust the equipment to prevent future shearing.

5. Coupling Wear:

Regular wear is normal for couplings, but excessive wear may lead to decreased performance and increased misalignment.

Diagnosis:

Inspect the coupling components for signs of wear, such as worn elastomeric elements or damaged teeth.

Fix:

Replace the worn or damaged components with new ones of the appropriate specifications.

Remember, regular maintenance and periodic inspection are key to diagnosing issues early and preventing severe problems. Always follow the manufacturer’s recommendations for maintenance and replacement schedules to ensure the proper functioning and longevity of the shaft coupling.

“`

editor by CX 2024-02-23

China manufacturer FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

SC Transmission FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

FCL Coupling/Shaft Coupling /Pin & Bush Coupling /FCL Flexible Coupling/NBK FCL Coupling is widely used for its compacts designing, easy installation, convenient maintenance, small and light weight.

As long as the relative displacement between shafts is kept within the specified tolerance, couplings will operate the best function and have a longer working life.

Thus it is greatly demanded in medium and minor power transmission systems driven by motors, such as speed reducers, hoists, compressors, conveyors, spinning and weaving machines and ball mills.

Product Parameters

| SIZE | D | D1 | d1 | L | C | n-M | kg | |||

| r/min | ||||||||||

| N.m | ||||||||||

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

Company Profile

FAQ

Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is It Possible to Replace a Shaft Coupling Without Professional Assistance?

Yes, it is possible to replace a shaft coupling without professional assistance, especially if you have some mechanical knowledge and the necessary tools. However, the ease of replacement can vary depending on the type of coupling and the complexity of the equipment. Here are some general steps to guide you through the process:

1. Safety First:

Before starting any work, ensure that the equipment is turned off and disconnected from the power source. Use appropriate personal protective equipment (PPE) to protect yourself from potential hazards.

2. Assess the Coupling Type:

Different types of couplings may have specific installation and removal methods. Identify the type of coupling you need to replace, and consult the manufacturer’s documentation or online resources for guidance.

3. Gather Tools and Materials:

Collect the necessary tools, such as wrenches, sockets, and a puller (if required), to safely remove the old coupling. Have the new coupling ready for installation, ensuring it matches the specifications of the old one.

4. Disassembly:

If your coupling is a split or clamp-style coupling, you may be able to replace it without fully disassembling the connected equipment. Otherwise, you may need to remove other components to access the coupling.

5. Remove Fasteners:

Loosen and remove any fasteners, such as set screws, that secure the old coupling to the shafts. Take care not to damage the shafts during this process.

6. Extraction:

If the old coupling is tightly fitted on the shafts, you may need to use a coupling puller or other appropriate extraction tools to safely remove it.

7. Clean and Inspect:

After removing the old coupling, clean the shaft ends and inspect them for any signs of damage or wear. Also, check for any misalignment issues that may have contributed to the old coupling’s failure.

8. Install New Coupling:

Follow the manufacturer’s instructions for installing the new coupling. Apply appropriate lubrication and ensure the coupling is correctly aligned with the shafts.

9. Fasten Securely:

Tighten the fasteners to the manufacturer’s recommended torque values to securely attach the new coupling to the shafts.

10. Test Run:

After installation, perform a test run of the equipment to ensure the new coupling operates smoothly and without issues.

While it is possible to replace a shaft coupling without professional assistance, keep in mind that some couplings and equipment may require specialized knowledge and tools for safe and proper replacement. If you are uncertain about the process or encounter any difficulties, it is advisable to seek help from a qualified professional or technician to avoid potential damage to the equipment or injury to yourself.

“`

Real-World Examples of Shaft Coupling Applications in Different Industries

Shaft couplings play a crucial role in various industries by connecting rotating shafts and transmitting torque between them. Here are some real-world examples of shaft coupling applications in different industries:

1. Manufacturing Industry:

In manufacturing plants, shaft couplings are used in various equipment such as conveyor systems, pumps, compressors, and mixers. For example, in a conveyor system, shaft couplings connect the motor shaft to the conveyor belt, allowing efficient material handling and transportation.

2. Oil and Gas Industry:

The oil and gas industry utilizes shaft couplings in applications like drilling rigs, pumps, and generators. In drilling rigs, couplings connect the motor to the drill shaft, enabling the drilling process.

3. Marine Industry:

In the marine industry, shaft couplings are found in propulsion systems, water pumps, and winches. They connect the ship’s engine to the propeller shaft, providing the necessary torque for propulsion.

4. Power Generation:

Power plants use shaft couplings in turbines, generators, and cooling systems. For instance, in a steam turbine, couplings connect the turbine to the electrical generator, allowing the conversion of steam energy into electrical power.

5. Aerospace Industry:

Aerospace applications use shaft couplings in aircraft engines, landing gear systems, and auxiliary power units. Couplings enable power transmission between different components of the aircraft systems.

6. Automotive Industry:

In vehicles, shaft couplings are present in the drivetrain, steering systems, and transmission. For example, in a car’s transmission system, couplings connect the engine to the gearbox, enabling smooth gear changes and power transmission to the wheels.

7. Mining Industry:

The mining industry relies on shaft couplings in heavy-duty machinery such as crushers, conveyor belts, and pumps. Couplings connect motors to various mining equipment, facilitating material extraction and transportation.

8. Agriculture:

Agricultural machinery like tractors and harvesters use shaft couplings to connect the engine to implements such as plows, harvesters, and irrigation pumps.

These examples demonstrate the wide-ranging applications of shaft couplings across industries. In each case, the specific coupling type is chosen based on factors such as torque requirements, misalignment compensation, environmental conditions, and load characteristics to ensure reliable and efficient operation.

“`

How Does a Flexible Shaft Coupling Differ from a Rigid Shaft Coupling?

Flexible shaft couplings and rigid shaft couplings are two distinct types of couplings, each designed to serve different purposes in mechanical power transmission. Here are the key differences between the two:

1. Flexibility:

The most significant difference between flexible and rigid shaft couplings is their flexibility. Flexible couplings are designed with elements that can deform or flex to accommodate misalignments between the shafts. This flexibility allows for angular, parallel, and axial misalignments, making them suitable for applications where shafts are not perfectly aligned. In contrast, rigid couplings do not have this flexibility and require precise alignment between the shafts.

2. Misalignment Compensation:

Flexible couplings excel in compensating for misalignments, making them ideal for applications with dynamic conditions or those prone to misalignment due to thermal expansion or vibrations. Rigid couplings, on the other hand, are used in applications where perfect alignment is critical to prevent vibration, wear, and premature failure.

3. Damping Properties:

Flexible couplings, particularly those with elastomeric or flexible elements, offer damping properties, meaning they can absorb and reduce shocks and vibrations. This damping capability helps protect the connected equipment from damage and enhances system reliability. Rigid couplings lack this damping ability and can transmit shocks and vibrations directly between shafts.

4. Torque Transmission:

Both flexible and rigid couplings are capable of transmitting torque from the driving shaft to the driven shaft. However, the torque transmission of flexible couplings can be limited compared to rigid couplings, especially in high-torque applications.

5. Types of Applications:

Flexible couplings find applications in a wide range of industries, especially in situations where misalignment compensation, vibration damping, and shock absorption are essential. They are commonly used in conveyors, pumps, compressors, printing presses, and automation systems. Rigid couplings are used in precision machinery and applications that demand perfect alignment, such as high-speed spindles and certain types of precision equipment.

6. Installation:

Flexible couplings are relatively easier to install due to their ability to accommodate misalignment. On the other hand, rigid couplings require careful alignment during installation to ensure proper functioning and prevent premature wear.

The choice between a flexible and a rigid shaft coupling depends on the specific requirements of the application. If misalignment compensation, damping, and flexibility are critical, a flexible coupling is the preferred choice. If precision alignment and direct torque transmission are essential, a rigid coupling is more suitable.

“`

editor by CX 2024-02-16

Best best made in China – replacement parts – PTO shaft manufacturer & factory Bkm063 garden tractor pto shaft Gearbox Worm Reduction Gear Motor Geared Transmission High Speed Reducer Helical Hypoid Manufacture Pto Planetary Electric Vehicle Iron Double Auto with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

baler pto shaft EPG tom woods 1350 jk Equipment international 1086 pto shaft removal is bush hog pto shaft lock pin situated 2007 jeep liberty front generate shaft in pto shafts at rural king XiHu bush hog pto clutch Spot bondioli & pavesi pto areas HangZhou dana driveshaft Zhejiang pto shaft protection chain ,China. It is 30km from our factory to HangZhou global airport.

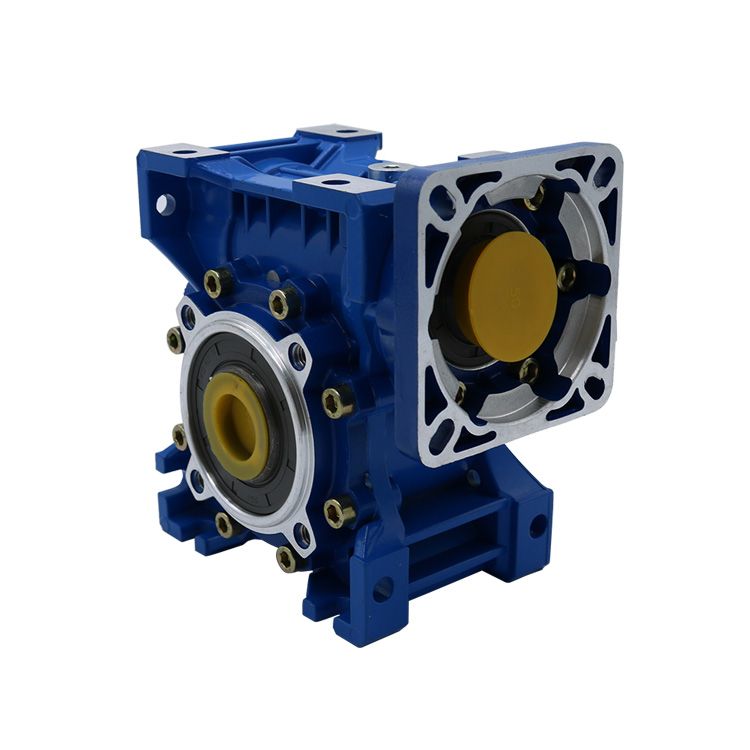

BKM063 Gearbox worm reduction gear motor geared transmission higher speed reducer helical hypoid manufacture PTO planetary electric powered car iron double vehicle

Solution Traits

1. Push by hypoid gear, has massive ratios.

two. Massive in output torque, high performance, energy preserving and environmental safety.

three. Created of higher quality aluminum alloy, mild in weight and non-rusting

four. Sleek in running and reduced in sounds, can perform extended in dreadful problems.

5. Great-seeking in physical appearance, sturdy in provider existence and modest in volume.

6. Ideal for all spherical set up, extensive application and simple of use.

seven. The Mounting Dimension of BKM sequence are suitable with NMRV collection worm equipment device (A element of NMRV050 dimensions are various from BKM050)

8. Modular and multi-framework can meet up with the requires of various situations.

| TYPE | BKM50,BKM63,BKM75,BKM90,BKM110 |

| Transmission Stage | B: 2 stages |

| C: 3 levels | |

| Ratio | B: 7.5,10,12.5,15,20,25,thirty,forty,50,60 |

| C: fifty,60,seventy five,one hundred,125,a hundred and fifty,200,250,three hundred | |

| Output torque | Up to 500N.m |

| Motor electricity | 0.12~5.5KW,with flange:B5 or B14 |

| Housing content | Aluminum alloy |

| Output shaft | material: 40Cr |

| Hardness degree: 242-286HB | |

| Helical gear | Material:20CrMnTi |

| Hardness amount: fifty eight-62HRC | |

| Precision level:6 grade | |

| Transmission performance | B:ninety two%-94% |

| C:ninety%-ninety two% | |

| Oil seal brand | SKF |

| Bearing | C&U |

| Lubricant | Mineral oil or artificial oil |

our firm

Nmrv best made in China replacement parts in Perm Russian Federation Aluminium Gearbox Transmission Gear Box Speed Reducer AC Motor with top quality

We – EPG Team the greatest gearbox & motors , couplings and gears manufacturing unit in China with 5 various branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

NMRV Aluminium Gearbox Transmission Equipment box Velocity Reducer IEC AC Motor

Specification

In depth Pictures

Other Relevant Goods

Firm Overview

ept Mechanical Products consist of:

one. AC gear motor

2. Brushed DC & brushless DC gear motor

three. Worm gearbox

4. Helical gearbox

5. Coreless motor

6. External rotor motor

7. Motor controller

8. Customized motor

ept Global Exhibitions:

ept CE Certificates:

We hope you appreciate cooperating with us.

If you are loo ept for a dependable vendor of any kinds of AC or DC motors and gear boxes, please freely get in touch with me. We will supply suitable travel solutions to you.

The use of first gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our organization and the shown alternative components contained herein are not sponsored, accredited, or produced by the OEM.

RV90 Custom made in China replacement parts in Konya Turkey Aluminum Worm Gear Reducer Motor with top quality

We – EPG Team the largest gearbox & motors , couplings and gears manufacturing facility in China with 5 distinct branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

NMRV worm gearbox motor

NMRV collection worm gear reducer:

Its structure,define and installation dimensions as nicely as functionality are identical with that of

Europe an goods,they are interchangeable,and the components and machining approach are innovative internationally.The merchandise is highlighted by:

one.Reduced sounds and temperature increase.

two.Large bearing capacity,easy run and prolonged provider existence.

three.ompact framework,samll volume,gentle fat,lovely shape and simple to put in.

four.Can operate continuously beneath server environment,and has a excellent trustworthiness.

ept NMRV aluminum worm gearbox motor information:

| Kind | ept NMRV Worm Gear Pace Reducer /gearbox motor |

| Model: | NMRV25/thirty/ forty/ 50/ 63/ 75/ 90/one hundred ten/a hundred thirty/150 |

| Enter Electricity: | .06KW,.09KW,.12KW,.18KW,.22KW,.25KW,.37KW,.55KW,.75KW,1.1KW,1.5KW,2.2KW,4KW,5.5KW,7.5KW ,11KW,15KW |

| IEC Flange | 56B5,56B14,63B5,63B14,71B5,71B14,80B5,80B14,90B5,90B14,100B5, 100B14,112B5,112B14 132B5,160B5 |

| Ratio | one: 7.5,10,fifteen,twenty,25,30,forty,50,60,eighty,100 |

| Material |

Housing: Die-Cast Aluminum Alloy for rv25-rv90 , die-forged forged iron for rv110 to rv150 |

| Worm Equipment-brass+forged iron | |

| Worm-20CrMn Ti with carburizing and quenching, surface area harness is 56-62HRC | |

| Shaft-chromium steel-forty five# | |

| Color: | Blue/Silver Or other folks if quantity is massive |

| Packing: | Carton or plywood Case |

| Guarantee time : | one Year except besides Man-made destruction |

| Usages: | Industrial Machine: Foods Stuff, Ceramics,CHEMICAL,Packing,Dyeing,Woodworking,Glass. |

| shaft: | output solid shaft or output hollow shaft |

FAQ

one, Q:what’s your MOQ for ac gearbox motor ?

A: 1pc is alright for every single sort electric powered equipment box motor

2, Q: What about your guarantee for your induction velocity reducer motor ?

A: a single year ,but except gentleman-manufactured wrecked

3, Q: which payment way you can accept ?

A: TT, western union .

4, Q: how about your payment way ?

A: a hundred%payment in innovative significantly less $5000 ,30% payment in advanced payment , 70% payment prior to sending over $5000.

five, Q: how about your pac ept of pace reduction motor ?

A: plywood scenario ,if dimension is tiny ,we will pack with pallet for much less 1 container

six, Q: What information should be provided, if I acquire electric powered helical geared motor from you ?

A: rated energy, ratio or output pace,type ,voltage , mounting way , amount , if much more is far better.

The use of unique products manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our firm and the shown replacement elements contained herein are not sponsored, authorized, or made by the OEM.

Nmrv toyota motor manufacturing japan near me shop made in China – replacement parts – Nrv in Aurangabad India Nmrv090 Worm Gear Speed Reduction Reducer Gearbo with top quality

We – EPG Group the greatest worm gearbox, couplings and gears manufacturing unit in China with 5 different branches. For far more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

NMRV REDUCTION WORM GEARBOX

The NMRV 090 worm equipment motor is an angular travel in which the input and output shafts are at appropriate angles to each other. A gearbox with one equipment phase provides gear ratios of 7.5 – 100. Electrical motor electricity: .37 – 4 kW. The travel can be mounted in an arbitrary spatial place. Mounting alternatives: flange or toes.

The unified mounting dimensions give the NMRV 090 gearmotor interchangeability with Varvel SRT 85, STM UMI ninety, SITI MU90 models.

Components components:

Situation – aluminum, flanges – aluminum, worm – metal, worm wheel crown – bronze.

Sort of lubricant: synthetic ISO VG 320.

Fat: 13 kg.

Kind designation scheme

NMRV – 090 – 30 – ninety three.3 – 2.2 – B7

- NMRV – worm equipment motor

- 090 – dimensions (middle distance, mm)

- thirty – gear ratio

- ninety three.3 – output shaft rotation speed, rpm

- two.2 – electric motor power, kW

- B7 – mounting position

NMRV 090 gearbox efficiency

| i | n one = 2800 rpm | n 1 = 1400 rpm | n 1 = 900, rpm | |||||||||

| n 2 , rpm |

T 2M , N * m |

P kw |

RD % |

n 2 , rpm |

T 2M , N * m |

P kw |

RD % |

n two , rpm |

T 2M , N * m |

P kw |

RD % |

|

| 7.five | 373 | 267 | 11.20 | ninety three | 187 | 363 | seven.80 | ninety one | a hundred and twenty | 432 | 6.ten | 89 |

| 10 | 280 | 266 | eight.eighty | 92 | one hundred forty | 368 | 6.00 | ninety | ninety | 430 | 4.60 | 88 |

| fifteen | 187 | 303 | 6.fifty nine | 90 | ninety three | 393 | 4.40 | 87 | 60 | 460 | 3.forty | eighty five |

| twenty | 140 | 312 | 5.twenty | 88 | 70 | 405 | three.50 | 85 | forty five | 470 | 2.70 | 82 |

| twenty five | 112 | 326 | 4.40 | 87 | 56 | 406 | two.ninety | 82 | 36 | 482 | 2.30 | seventy nine |

| 30 | ninety three | 314 | 3.sixty | 85 | forty seven | 374 | 2.thirty | 80 | 30 | 466 | 1.90 | seventy seven |

| 40 | 70 | 358 | 3.twenty | 82 | 35 | 441 | 2.ten | 77 | 23 | 492 | 1.sixty | seventy four |

| 50 | 56 | 319 | 2.40 | 78 | 28 | 398 | 1.60 | 73 | 18 | 483 | 1.thirty | 70 |

| sixty | 47 | 303 | 2.00 | seventy four | 23 | 372 | 1.thirty | 69 | fifteen | 414 | 1.00 | 65 |

| eighty | 35 | 264 | 1.forty | 69 | eighteen | 306 | 0.ninety | 64 | 11 | 378 | 0.70 | 62 |

| one hundred | 28 | 233 | 1.ten | sixty two | 14 | 272 | 0.70 | 57 | nine | 281 | 0.50 | 53 |

- n1 – rotational pace el. motor

- n2 – revolutions on the output shaft

- T 2M – torque on the output shaft

- P is the optimum allowable engine electricity

- RD – performance

GEARBOX Attribute

| 1.Good high quality,extended daily life time,low sounds. |

| two.Compact,hassle-free. |

| three.Substantial effectiveness,large torque. |

Total and mounting dimensions NMRV 090

NMRV090 gear motor has a wide assortment of equipment ratios.

Gear ratios: 7.5, 10, fifteen, twenty, twenty five, thirty, 40, fifty, sixty, 80, one hundred .

Output flange to NMRV 090 gearbox

Geared NMRV090 can be equipped with unilateral or bilateral output shaft.

The gearbox arrives regular with a hollow output shaft

A torque arm is an added alternative to the gearbox.

| Model | NMRV Series |

| Single Stage | RV25-RV150 |

| Ratio | 7.5-a hundred |

| Input Electrical power | 0.06KW-15KW |

| Output Pace | 14-280rpm |

| Output Torque | 5-1800Nm |

| Main parts | worm wheel,worm shaft |

| Core areas materials | worm shaft:20 Cr Mn Ti,worm wheel:Nodular forged iron interal,9-4 copper exterior |

| Lubrication | RV30-ninety:artificial oil, RV110-a hundred and fifty:GN460-W mineral oil |

| Bearings | C&U |

/ The use of authentic products manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our organization and the detailed substitution components contained herein are not sponsored, accepted, or made by the OEM. /

450V near me made in China – replacement parts – in Vancouver Canada Three Phase EPT ro AC Induction Gear Motor with Reducer with top quality

We – EPG Team the greatest gearbox & motors , couplings and gears factory in China with 5 diverse branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Technical specs

1) Dimensions of device: 42mm, 60mm, 70mm, 80mm, 90mm, 104mm

2) Power: 6W, 15W, 25W, 40W, 60W, 90W, 120W, 140W

three) Voltage Poles: Single-Section 100V fifty/60Hz 4P

Single-Phase 110V 50/60Hz 2P

Single-Stage 110V 50/60Hz 4P

Solitary-Phase 110V 50/60Hz 2P

Solitary-Section 110V,120V 60Hz 4P

One-Phase 220V,120V 60Hz 4P

A few-Section 200/220/230V 50/60Hz 4P

Three-Section 380/415V 50/60Hz 4P

Three-Section 200/220/230V 50/60Hz 2P

Three-Section 380/415V 50/60Hz 2P

4) Equipment ratio of the Equipment Head: 3, 3.6, 5, 6, 7.5, 9, twelve.5, 15, 18, 25, thirty, 36, 50, sixty,seventy five,ninety,one hundred,120,150,a hundred and eighty,250

We are specialised in Mini AC Equipment Motor. Our primary products are used for MachineTools, Textile Equipment, Health care Appliance, Conveying Device, Printing System, Food Machinery, Vending Machine, Pac ept Machinery, Gumming Machine and so on. We supply consumers with prime quality products and fine provider. You should get in touch with us if you have any query or inquiry.

Our reduction geared motor Gain

one,reasonable price with superb quality

two,shipping in time

three,safe ,reputable ,affordable and durable

four,secure transmission ,quiet operation

5,easy managing and minimal noise

six,great appearance ,resilient service life

7,large heat-radiating performance ,large carrying ability

eight,each gearbox need to be tested prior to packing

nine.reply in large effectiveness in the course of one wor ept day

ten. specialist to create gearbox and electric powered motor .

FAQ

one, Q:what is your MOQ for ac gearbox motor ?

A: 1pc is okay for every type electric equipment box motor

2, Q: What about your warranty for your induction speed reducer motor ?

A: 1 12 months ,but besides man-made wrecked

3, Q: which payment way you can accept ?

A: TT, western union .

four, Q: how about your payment way ?

A: one hundred%payment in innovative considerably less $5000 ,thirty% payment in advanced payment , 70% payment before sending more than $5000.

five, Q: how about your pac ept of velocity reduction motor ?

A: plywood situation ,if measurement is modest ,we will pack with pallet for less a single container

6, Q: What data ought to be presented, if I buy electric powered helical geared motor from you ?

A: rated electrical power, ratio or output speed,sort ,voltage , mounting way , amount , if a lot more is far better ,

The use of authentic products manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our firm and the shown substitution components contained herein are not sponsored, authorized, or produced by the OEM.

Best China manufacturer & factory high quality Precision 8-10 arcs RW worm gearbox rw50 reducer gear motor for stepper motor supplier With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racWe are committed to giving our customers a clear competitive edge with our products – and this can only be achieved with unconventional thinking and a constant search for improvements. This is why our solutions operate reliably in the most extreme conditions and set industry standards in power density or service life.ks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product name:

-

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

NMRV RW worm gear reducer motor

- Housing Material:

-

Aluminum Steel

- Certificate:

-

ISO9001

- Ratio:

-

5~300

- Bearing:

-

NSK Bearing

- Gear material:

-

45# Cast Steel

- Mounting Position:

-

Flange Mounted

- Output torque:

-

2.6-1195N.M

- Color:

-

Customer Request

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 2 3 – 5 >5 Est. Time(days) 4 10 To be negotiated

Online Customization

Product Description

NMRV NRV SERIES WORM GEAR SPEED REDUCER

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

|

NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 |

||||||

|

NMRV |

Worm geared motor |

|||||

|

NRV |

Worm reduction unit |

|||||

|

063 |

center dictance |

|||||

|

30 |

Reduction ratio |

|||||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|||

|

AS |

Single output shaft |

AB |

Double output shaft |

|||

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|||

|

0.75KW |

Electric motor power |

B3 |

Mounting position |

|||

PRECISION BEVEL GEAR

worm and gear: The gears are made of 10-1 tin bronze (with high strength, corrosion resistance and excellent casting properties).

Worm adopts 20CR:carburized alloy structural steel (with high strength, hardenability, wear resistance).

High Speed Bearings and SKF Seals:Use synthetic oil (friction agent: reduce temperature rise, reduce friction).

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Output Flange Mounting Dimensions

NMRV NRV SERIES WORM GEAR SPEED REDUCER FEATURES:

● The weight of the NMRV reducer is relatively light. The shell is made of aluminium alloy. It has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long service life, no noise and so on. It is easy to connect with the motor.

● NMRV reducer is a more practical transmission equipment, and in the appearance design and its integration are more in line with the needs of the public than other types of reducers.

●The application field and popularity of the RV reducer made of aluminium alloy are even better than other types of reducer. It is a kind of reducer with high practicability, and also a combination of advanced technology at home and abroad.

● NMRV reducer is very convenient to connect with ordinary motor, CVT, flange electromagnetic clutch brake unit, and does not need coupling. Suitable for all-round installation, and the output torque It is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement. is relatively large, work fairly smoothly and so on.

Our Company

Zhejiang provice EPT – one of the Biggest Transmission manufactrer in China GEAR TECHNOLOGY CO., LTD

Our company is located in the city of HangZhou ( Beautiful city where West lake located ) , Zhejiang provice Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

NMRV NRV worm gear speed reducer.

It is widely used in many fields such as metallurgy, mine, printing, chemical industry, textile, foodstuff, medicine, rubber and plastic,etc.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or amanufacturer?

A: We are a manufacturer in Zhejiang provice Province, China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply as soon as possible, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

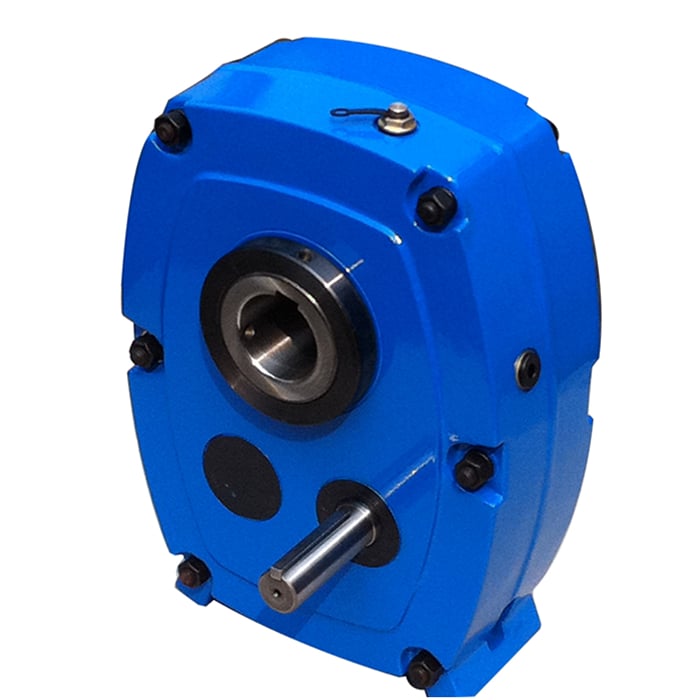

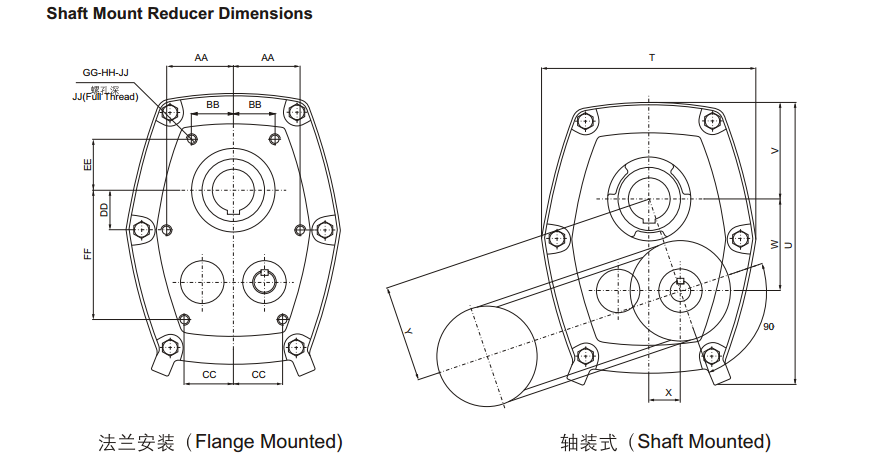

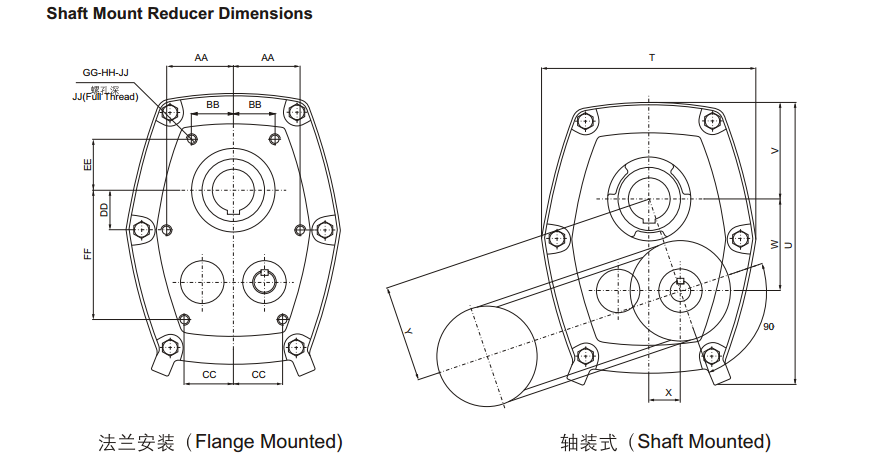

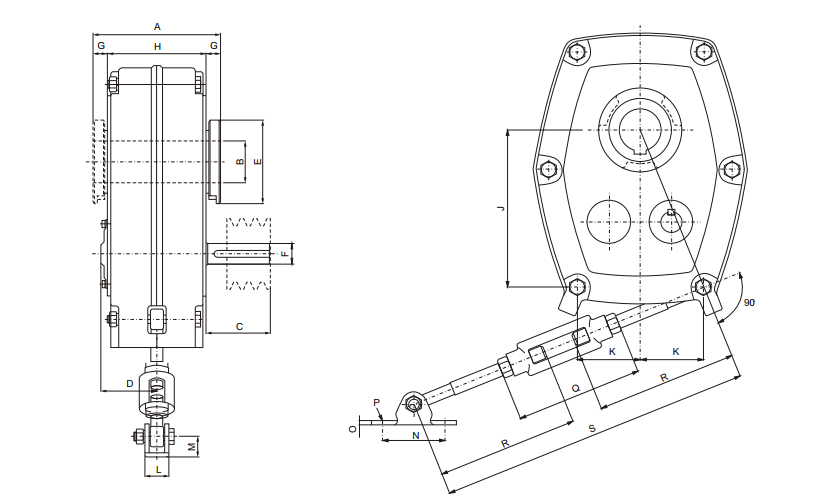

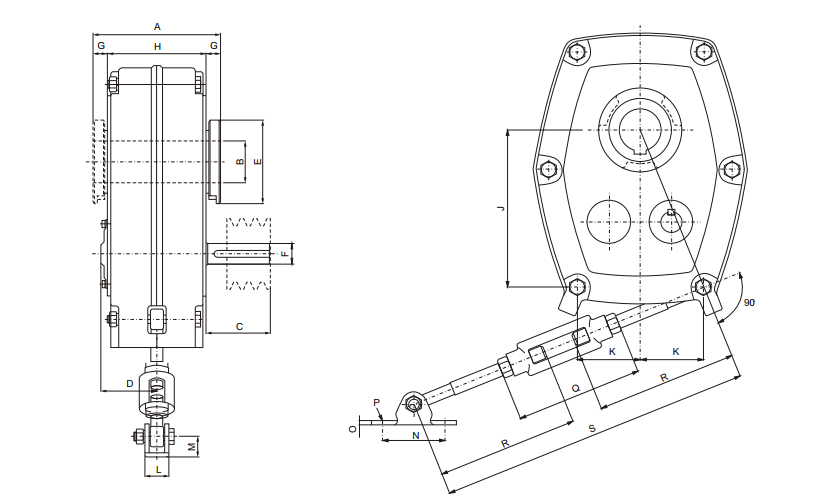

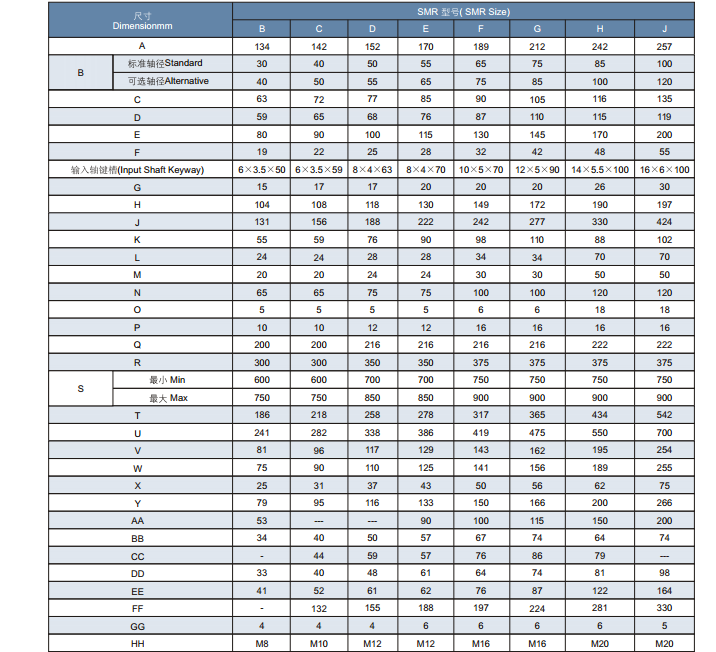

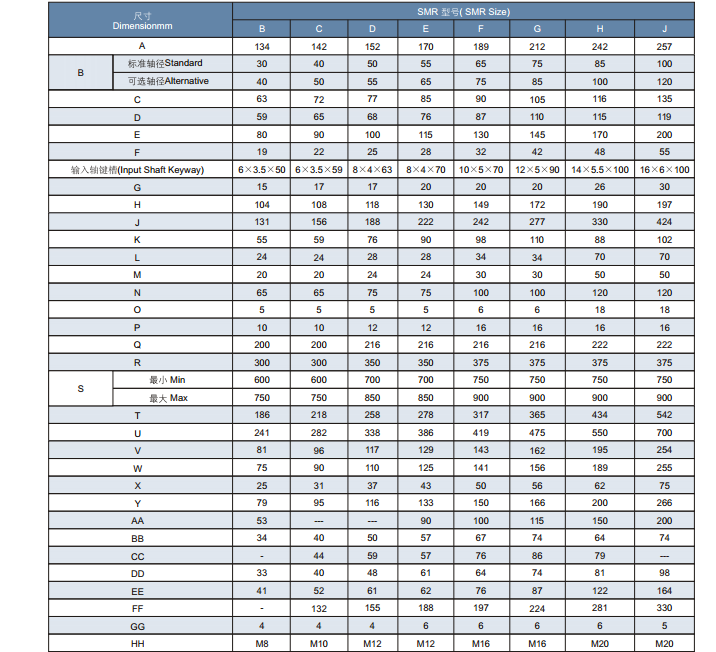

Best China manufacturer & factory SMR Shaft Mounted worm gear motor reducer With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

Overview

In addition to our two sales offices in the US, EPG employs a nationwide network of sales partners who will provide expert technical support to your company.

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

max 8000NM

- Input Speed:

-

1440

- Output Speed:

-

72, 110, 288

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

SMR

- Rated Power:

-

2.68~134.2

- color of Shaft Mounted speed reducer:

-

green blue gray

Supply Ability

- Supply Ability:

- 500 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- standard export packing and wood pallets packing

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Quantity(Boxes) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

Product Description

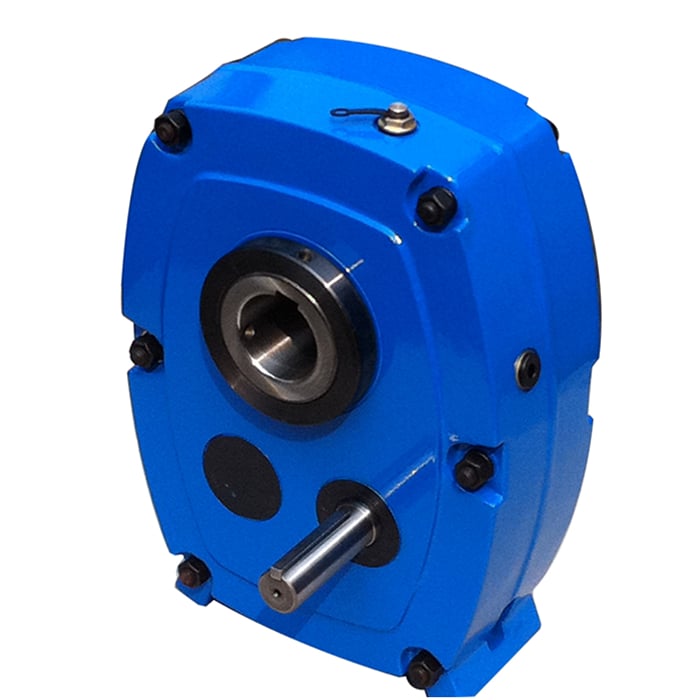

SMR Shaft Mounted worm gear motor reducer

1. Precision High Quality Gearing

Computer designed helical gears, strong alloy materials for high load capacity, ground profile (some intermediate pinions are shaved). Crown tooth profile, in conformance with ISO 1328-1997, 98% efficiency for per stage, smooth quiet operation with several teeth in mesh.

2. Output Hub

*Standard or alternative output hole diameter for choice as follow.

|

ITEM |

Standard output hole diameter |

Alternative output hole ø |

|

B5 |

ø30 |

ø25/35/40 |

|

B13/20 |

ø30 |

ø25/35/40 |

|

C5 |

ø40 |

ø35/45/50 |

|

C13/20 |

ø40 |

ø35/45/50 |

|

D5 |

ø50 |

ø45/55/60/65 |

|

D13/20 |

ø50 |

ø45/55/60/65 |

|

E5 |

ø55 |

ø50/60/65 |

|

E13/20 |

ø55 |

ø50/60/65 |

|

F5 |

ø65 |

ø60/70/75 |

|

F13/20 |

ø65 |

ø60/70/75 |

|

G5 |

ø75 |

ø70/80/85 |

|

G13/20 |

ø75 |

ø70/80/85 |

|

H5 |

ø85 |

ø80/90/95/100 |

|

H13/20 |

ø85 |

ø80/90/95/100 |

|

J5 |

ø100 |

ø90/95/105/110/105120 |

|

J13/20 |

ø100 |

ø90/95/105/110/105120 |

3. Strong Alloy Steel Shafts

Strong alloy steel, hardened, ground on journals, gear seatings and extensions, for maximum torsional loads. Generous size shaft keys for shock loading and conform to ISO standards.

4, Back Stops

Alternative parts, anti-run back device, are available on all 13:1 and 20:1. Ratio units and do not recommend for 5:1.

5. TorMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.que Arm Assembly

For easy adjustment of the belt.

Detailed Images

Related Products

Certifications

Packing & Delivery

Packing Images of SMR Shaft Mounted worm gear motor reducer

Inner Packing: PP bag with carton;

Outer Packing: Wooden case;

Shipment: 20-30 days upon receiving the deposit.

About Us

About Hangzhou Ever-power group(HZPT):

Q: Are you trading company or manufacturer ?

A: HZPT group consists in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 30-45 days. The time may vary depending on the product and the level of customization. For standard products,

the payment is: 30% T/T in advance ,balance before shippment.,for customized products,50% downpayment is requested normally.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with detail size, material and further specifications;when you place orders,pleasure contact us in advance to communicate all details

Best China manufacturer & factory China manufacturer CH CV AC single-phase gear speed reducer motor With high quality best price

We offer OEM service.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Product Name:

-

CH CV AC single-phase gear speed reducer motor

- Application:

-

Industry Machine

- Name:

-

Synchronous Gear Motor

- Speed:

-

High Speed

- Motor Name:

-

Speed control motor

- Usage:

-

Machine Tools

Supply Ability

- Supply Ability:

- 1000 Piece/Pieces per Month

Packaging & Delivery

- Port

- shanghai

Online Customization

Product Description

1.GV series gear reducer motor adopts totally enclosed electromechanical integration design.

2. Hard tooth surface helical gear transmission, low noise and high efficiency.

3. The whole structure is small, the weight is light, and the adaptability is strong.

4. The electromagnetic brake can be attached.

Application Areas

Four series: blender, metallurgical machinery, power machinery, mining transport line, environmental machinery, road building machinery, chemical machinery, cement machinery, water conservancy machinery and petroleum machinery.

Medium speed reducer and micro reducer: production line, die cutting machine, quilting machine, industrial washing machine, woodworking machinery.

Planetary gear reducer is widely used in automation equipment, such as packaging equipment, lithium electrical equipment, electronic equipment, LED equipment, etc.

Detailed Images

Our Company

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting……

Application area

Certifications

Why choose us

Packing & Delivery

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZheJiang China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: WithinIndustrial Reducers EPG Drive offers two types of industrial gearbox, covering standard duty through to heavier duty and severe duty applications seen in some of the world’s most inhospitable mining sites. 12 hours.

Q4: How long should I wait for the feedback after I send the enquiry?

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Contact us

Mobile: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd.