Product Description

HangZhou CHINAMFG Precision Industry Co.,Ltd

The company has owned IS0 9001 (International Quality Management) system certification, ISO14001 (International Environmental Management) system certification, IATF16949 (International Automotive Task Force) system certification and EN15085-2 (Railway applications-Welding of railway vehicles and components) system certification. We have an experienced management team and a group of high-quality talents.

Our advantages are as below.

- Core Value: Integrity + Quality;

- Rich Experience: Since the year of 2001;

- Technical Engineer: 36 Staffs;

- Quality Engineer: 18 Staffs;

- Company Certificate: ISO 9001, ISO14001, ITAF 16949, EN 15085-2;

- Strong Capacity: Up to 100k pieces per day;

| Factory Description and Service Content | ||||||||||||||||||||||

| PRODUCTION LINE: | Metal stamping, Laser cutting, Sheet metal, Welding, Spraying, Electrophoresis, Assembly. | |||||||||||||||||||||

| MATERIAL: | Carbon steel, Stainless steel, Aluminum, Copper, Brass, Bronze, Customized. | |||||||||||||||||||||

| PROCEDURES: | Blanking, Punching, Bending, Cutting, Milling, Dilling, Tapping, Riveting, Welding, Assembling, Packing. | |||||||||||||||||||||

| TOLERANCE: | +/- 0.01mm | |||||||||||||||||||||

| FINISH: | Powder, Spraying, Sand Blasting, Electroplating, Electrophoresis, Anodizing, Passivating, Customized. | |||||||||||||||||||||

| COLOR: | Natural, Conversonial, Silver, Grey, Black, White, Red, Blue, Green, Yellow, Matte, Glossy, Customized. | |||||||||||||||||||||

| SYSTEM CERTIFICATION: | ISO 9001, ISO 14001, ITAF 16949, EN 15085-2. | |||||||||||||||||||||

| APPLICATION: | Automobile, Communication, Electrical, Electronics, Rail transit, Equipment manufacturing etc. | |||||||||||||||||||||

| MOQ: | 1,000 Pcs ~ 5,000 Pcs | |||||||||||||||||||||

| MOULD COST: | 500 USD ~ 5,000 USD | |||||||||||||||||||||

| UNIT PRICE: | 0.05 USD ~ 5.00 USD | |||||||||||||||||||||

| PACKING: | Paper Bag, Plastic Bag, PE Bag, Carton Board, Carton Box, Plywood case, Wooden Case, Pallet. | |||||||||||||||||||||

| MPQ: | 50 Pcs ~ 200 Pcs | |||||||||||||||||||||

| LEAD TIME: | 15 Work Days ~ 25 Work Days | |||||||||||||||||||||

| TRADE TERM: | EXW, FOB, CFR, CIF, DDU, DDP. | |||||||||||||||||||||

| PAYMENT METHOD: | T/T, L/C, Western Union, Money Gram, PayPal, Ali Pay. | |||||||||||||||||||||

Workshop Inner View

System Certificate

Production Line View

Metalworking products are very important component in industrial field, It is widely accepted for its stable performance and affordable price.

Especially in the field of Automobile, Communication, Electrical, Electronics, IT, Equipment Manufacturing, Rail Transit and Construction etc.

We committed to provide our customers with excellent products and cater to their demand solutions with lower costs and highly efficiency. Please feel free to contact us, we are looking CHINAMFG to our further cooperation. We treat every customer sincerely and take every project seriously.

| FAQ:

1. Why business with CHINAMFG Precision Co., Ltd? 2. Are the products available for selling from your Product Display Area? 3. How to get your quotation? 4. What’s your production leadtime? 5. How to guarantee the products quality? |

Is It Possible to Replace a Shaft Coupling Without Professional Assistance?

Yes, it is possible to replace a shaft coupling without professional assistance, especially if you have some mechanical knowledge and the necessary tools. However, the ease of replacement can vary depending on the type of coupling and the complexity of the equipment. Here are some general steps to guide you through the process:

1. Safety First:

Before starting any work, ensure that the equipment is turned off and disconnected from the power source. Use appropriate personal protective equipment (PPE) to protect yourself from potential hazards.

2. Assess the Coupling Type:

Different types of couplings may have specific installation and removal methods. Identify the type of coupling you need to replace, and consult the manufacturer’s documentation or online resources for guidance.

3. Gather Tools and Materials:

Collect the necessary tools, such as wrenches, sockets, and a puller (if required), to safely remove the old coupling. Have the new coupling ready for installation, ensuring it matches the specifications of the old one.

4. Disassembly:

If your coupling is a split or clamp-style coupling, you may be able to replace it without fully disassembling the connected equipment. Otherwise, you may need to remove other components to access the coupling.

5. Remove Fasteners:

Loosen and remove any fasteners, such as set screws, that secure the old coupling to the shafts. Take care not to damage the shafts during this process.

6. Extraction:

If the old coupling is tightly fitted on the shafts, you may need to use a coupling puller or other appropriate extraction tools to safely remove it.

7. Clean and Inspect:

After removing the old coupling, clean the shaft ends and inspect them for any signs of damage or wear. Also, check for any misalignment issues that may have contributed to the old coupling’s failure.

8. Install New Coupling:

Follow the manufacturer’s instructions for installing the new coupling. Apply appropriate lubrication and ensure the coupling is correctly aligned with the shafts.

9. Fasten Securely:

Tighten the fasteners to the manufacturer’s recommended torque values to securely attach the new coupling to the shafts.

10. Test Run:

After installation, perform a test run of the equipment to ensure the new coupling operates smoothly and without issues.

While it is possible to replace a shaft coupling without professional assistance, keep in mind that some couplings and equipment may require specialized knowledge and tools for safe and proper replacement. If you are uncertain about the process or encounter any difficulties, it is advisable to seek help from a qualified professional or technician to avoid potential damage to the equipment or injury to yourself.

“`

Do Shaft Couplings Require Regular Maintenance, and if so, What Does it Involve?

Yes, shaft couplings do require regular maintenance to ensure their optimal performance, extend their service life, and prevent unexpected failures. The maintenance frequency may vary based on factors such as the coupling type, application, operating conditions, and the manufacturer’s recommendations. Here’s what regular maintenance for shaft couplings typically involves:

1. Visual Inspection:

Regularly inspect the coupling for signs of wear, damage, or misalignment. Check for cracks, corrosion, and worn-out elastomeric elements (if applicable). Look for any abnormal movement or rubbing between the coupling components during operation.

2. Lubrication:

If the shaft coupling requires lubrication, follow the manufacturer’s guidelines for the appropriate lubricant type and frequency. Lubrication helps reduce friction, wear, and noise in the coupling.

3. Alignment Check:

Monitor shaft alignment periodically. Misalignment can lead to premature coupling failure and damage to connected equipment. Make adjustments as needed to keep the shafts properly aligned.

4. Torque Check:

For bolted couplings, periodically check the torque on the bolts to ensure they remain securely fastened. Loose bolts can lead to misalignment and reduce coupling performance.

5. Replace Worn Components:

If any coupling components show signs of wear or damage beyond acceptable limits, replace them promptly with genuine replacement parts from the manufacturer.

6. Environmental Considerations:

In harsh environments with exposure to chemicals, moisture, or extreme temperatures, take additional measures to protect the coupling, such as applying corrosion-resistant coatings or using special materials.

7. Monitoring Coupling Performance:

Implement a monitoring system to track coupling performance and detect any changes or abnormalities early on. This could include temperature monitoring, vibration analysis, or other condition monitoring techniques.

8. Professional Inspection:

Periodically have the coupling and connected machinery inspected by qualified professionals to identify any potential issues that may not be apparent during regular inspections.

By adhering to a regular maintenance schedule and taking proactive measures to address potential issues, you can ensure that your shaft couplings operate reliably and efficiently throughout their service life, minimizing downtime and improving overall system performance.

“`

Can a Damaged Shaft Coupling Lead to Equipment Failure and Downtime?

Yes, a damaged shaft coupling can lead to equipment failure and downtime in mechanical power transmission systems. Shaft couplings play a critical role in connecting rotating shafts and transmitting power between them. When a coupling becomes damaged or fails to function properly, several negative consequences can arise:

1. Misalignment Issues:

A damaged coupling may no longer be able to compensate for misalignments between the connected shafts. Misalignment can cause excessive vibration, increased wear, and premature failure of bearings and other connected components. Over time, these issues can lead to equipment breakdown and unplanned downtime.

2. Vibration and Shock Loads:

Without the damping properties of a functional coupling, vibrations and shock loads from the driven equipment can transmit directly to the driving shaft and other parts of the system. Excessive vibrations can lead to fatigue failure, cracking, and damage to the equipment, resulting in reduced operational efficiency and increased downtime.

3. Overloading and Torque Transmission:

A damaged coupling may not effectively transmit the required torque between the driving and driven shafts. In applications where the coupling is a safety device (e.g., shear pin couplings), failure to disengage during overloading situations can lead to equipment overload and damage.

4. Increased Wear and Tear:

A damaged coupling can lead to increased wear on other parts of the system. Components such as bearings, seals, and gears may experience higher stress and wear, reducing their lifespan and increasing the likelihood of breakdowns.

5. Reduced System Reliability:

A functional shaft coupling contributes to the overall reliability of the mechanical system. A damaged coupling compromises this reliability, making the system more prone to failures and unplanned maintenance.

6. Downtime and Production Loss:

When a shaft coupling fails, it often results in unscheduled downtime for repairs or replacement. Downtime can be costly for industries that rely on continuous production processes and can lead to production losses and missed delivery deadlines.

7. Safety Hazards:

In certain applications, such as heavy machinery or industrial equipment, a damaged coupling can create safety hazards for workers and surrounding equipment. Sudden failures or uncontrolled movements may pose risks to personnel and property.

Regular inspection, maintenance, and prompt replacement of damaged shaft couplings are essential to prevent equipment failure, minimize downtime, and ensure safe and efficient operation of mechanical systems. It is crucial to address any signs of coupling wear or damage immediately to avoid potential catastrophic failures and costly disruptions to operations.

“`

editor by CX 2023-11-28

Ball made in China – replacement parts – in Vancouver Canada Mill Pinion Gear for Ball Mill Factory Customized High Precision Motor Meter Gear with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Girth gears are thoroughly used in mo EPT of the mil EPT and kiln generate method. These gears are one particular of the highe EPT co EPT elements in the complete drive assembly. The girth gears have a extremely large diameter and higher precision finish. The girth gears have a high performance and its all round life relies upon on the proper lubrication and alignment.

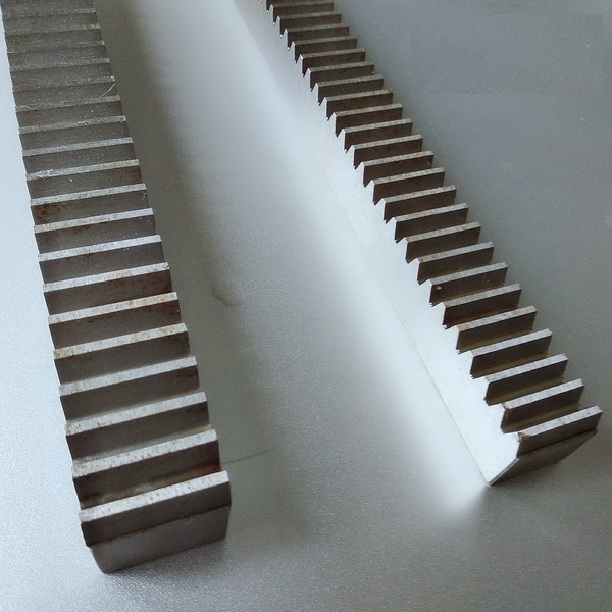

The approach of gear generation

Measuring the tooth area and precision of equipment

Engineer and the packing of the equipment

The previously mentioned are our actual workshops, welcome to check out!

| Specification | Machining Scope |

| Dimensions | OD Max 16m |

| One piece of Equipment:OD Max 13m | |

| Assemble Gear:In accordance to drawings | |

| Hobbing Modulds | ten-sixteen |

| Milling Modulus | Up to a hundred and twenty |

| Spiral Quality | 1-15 |

| Accuracy Grade | Milling: 6 grade |

| Hobbing:8 grade | |

| Materials | Alloy metal:42CrMo4,34CrNiMo6 and so on. |

| Carbon metal:C45E, 1030 | |

| Carburizing metal | |

| Quenched and tempered steel | |

| Coronary heart remedy | Quenching&Tempering, Surface Quenching |

| Enamel Profile | Spur, Helical, Herringbone, Crown, Spiral, Worm and shaft |

We can supply OEM Service for Gear Metal Castings, and individuals metal castings can be produced in the adhering to circumstances:

- Warmth remedy: Normalized, Normalized and Tempered, Quenched and Tempered

- Machining: Rough machined, Semi-concluded machined, Concluded machined

- Non-Damaging Tests: Magnetic Particle Testing, Ultrasonic Screening, Penetrant Screening

- Substance: Carbon Steel, Alloy Metal, fulfill ASTM, BS, DIN, NF, JIS, ISO normal

- Personal Bodyweight: 500KG – 140MT

Software:

- Mining

- Metallurgy

- Power Technology

- Cement Plant

- Port Machinery

Quality Control: UT,MT,RT,PT,chemical composition test,mechanical property test,and many others.

Surface Treatment: Painting,plating,sharpening,black oxide,transparent anti-rust oil.

Inspection: Besides our in-house inspection, you could also choose a third party inspection.

Common: GB, JIS, AISI, SAE, ASTM/ASME, EN, DIN, GOST

Certification: Raw material certificate(material chemical composition)

Heat treatment sheet report

Dimension inspection report

UT test report

We can also manufacture Bevel Gears, Helical Gear, Cylindrical Gear and many others. Welcome your custom drawing.

Firm Introduction

EVON bearings,worms drives, slewing bearings, gears, shaft demonstrate every single day to be crucial structural and relationship aspects , they can be extensively utilised in lifting & transport machinery, mining equipment,development machinery, port hoisting machinery, port oil transfer products, onshore and offshore crane, excavator, concrete device, paper device, plastic and rubber equipment, weave equipment, cement plant, steel plant, coal plant digital electrical power plant, wind electricity generator, EPT construction and industry devices or equipments and EPT massive rotary system.

Almo EPT all EVON merchandise are exported, largely to international locations of the European Union, the United states of america, the Middle East, the South American, the Africa, the Austrilian and Asia locations and to the Russian Federation. Through daughter firms in the EVON Team and a community of contracted dealers, In the procedure of cooperation with our clients, we have made it a principle to set up a long lasting and fulfilling partnership with our buyers by supplying effective provider with best quality and reducing the price.

Xihu (We EPT Lake) Dis.g for steady commitment to good quality and consumer provider, Evon EPT attaches wonderful value to study and growth to guarantee greater solution top quality and services from its extremely establishment. The good quality of EVON items are based on exceptional speciali EPT and technical degree of constructors and specialists, hugely experienced operators, knowledgeable manufacturing employees and we mu EPT not fail to remember the mo EPT modern day generation and testing equipment and equipment.

The use of original products manufacturer’s (OEM) component figures or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our business and the detailed substitution elements contained herein are not sponsored, accredited, or made by the OEM.

Best China manufacturer & factory high precision Drive Planetary Crown Wheel And Pinion Toy Right Angle Bevel Gear With high quality best price

Quality and credit are the bases that make a corporation alive. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

0.4-20

- Service:

-

Reply in 12 hours at any time

- Normal material:

-

20CrMnTi

-

Material2:

A power take-off or power takeoff (PTO) is any of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine. -

Steel, Stainless steel, POM etc.

- Heat treatment:

-

Teeth hardened HRC55-63

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Antirust oil + Paper bag + Wooden case

- Port

- Ningbo, Shanghai or as request

-

Lead Time

: -

Quantity(Bags) 1 – 200 201 – 500 501 – 2000 >2000 Est. Time(days) 30 The centering machine is part of the worm-gear assembly line. An operator loads the reducer housing and bearing cover, and the machine determines the spacing between output bearing seats.

40 60 To be negotiated

Online Customization

high precision Drive Planetary Crown Wheel And Pinion Toy Right Angle Bevel Gear

Spiral bevel gears

Our spiral bevel gears are welcomed by many customers for its stable high quality and competitive price.

The producing character of JH spiral bevel gears:

1. Gear size: the biggest diameter is 1800mm;

2. Material: Most common steel is high strength steel 20CrMnTi. Others can be steel C45, stainless steel, high strength steel, copper, aluminium, plastic, POM etc;

3. Spiral bevel Gear module: 0.3-20 (pitch from 0.942-62.80mm, DP 1.27-85);

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering etc.

5. Quality: stable and high, grade 7 for without teeth grinding, grade 6 after teeth grinding, grade 5 for precise grinding.

Prices for above quality are very competitive for us.

6. Heat treatment: teeth can be hardened to HRC 55-63.

The quality character of JH spiral bevel gears:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The teeth can be ground to grade 6 and grade 5 quality;

4. The bore will be polished to smooth and high precision;

5. The price is competitive even the quality is high.

| Facilities |

Machining center, Gleason machines, CNC gear hobbing machine, CNC gear shaper, CNC gear grinding machine, CNC turning machine, CNC milling machine, Y58200 CNC large gear rack shaper, Y58125A gear rack shaper, England gear rack shaper, and Russia gear rack shaper, |

| Gear types |

Helical gears (more and more widely used for its stable transimission); Spur gears; Hub gears; Bevel gears; Bevel spiral gears; Gear ring; etc. |

| Material |

Steel: C45, Q235, 40Cr, 20CrMnTi, etc. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 etc. Aluminium alloy: 6061, 5083, 7050, etc. More: PA6, PA66, POM, ABS etc. |

| Surface | Polishing; Plating; Galvanized; Blacken; chromium plating, nickel plating; painting etc. |

Full experience on Spiral bevel gears

Our Services

1. Delivery time: 15-25 days for small order;

30-45 days for big order. (Never delayed till now)

Can be discussed for more urgent order.

2. Response time: usually in 1 hour and in 12 hours even in our holidays.

3. Process feedback: Photos or vedios will be sent for 2-3 times to inform you the producing situation.

4. Test report: The test report can be offered as request.

5. Payment terms: T/T, L/C, D/P, D/A, O/A, M/T, D/D etc.

6. Trade terms: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Information

FAQ

Q: Manufacturer?

A: Yes. Since 2004 only focus on producing high quality gears and racks.

Q: Response time?

A: Reply very soon, and reply in 12 hours at any time.

Our technicians are always together with salesmen, so your any questions can be replied very soon.

Q: Price?

A: Drawings are more appriated for quotation. Or, please inform us your request, we will make drawings for your check.

QMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.: Delivery time?

A: 15-25 days for small order (<200 pcs), 30-45 days for large order.

Orders never be delayed, the products will be sent on time as agreement.

Q: Quality?

A: Middle and high quality is more competitive.

Q: Payment terms?

A: T/T for less than US$20,000 order, and L/C, D/P, D/A, O/A, M/T, D/D etc. for large orders.

Q: Trade terms?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Hot related products

Contact us

Best China manufacturer & factory high quality Precision 8-10 arcs RW worm gearbox rw50 reducer gear motor for stepper motor supplier With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racWe are committed to giving our customers a clear competitive edge with our products – and this can only be achieved with unconventional thinking and a constant search for improvements. This is why our solutions operate reliably in the most extreme conditions and set industry standards in power density or service life.ks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product name:

-

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

NMRV RW worm gear reducer motor

- Housing Material:

-

Aluminum Steel

- Certificate:

-

ISO9001

- Ratio:

-

5~300

- Bearing:

-

NSK Bearing

- Gear material:

-

45# Cast Steel

- Mounting Position:

-

Flange Mounted

- Output torque:

-

2.6-1195N.M

- Color:

-

Customer Request

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 2 3 – 5 >5 Est. Time(days) 4 10 To be negotiated

Online Customization

Product Description

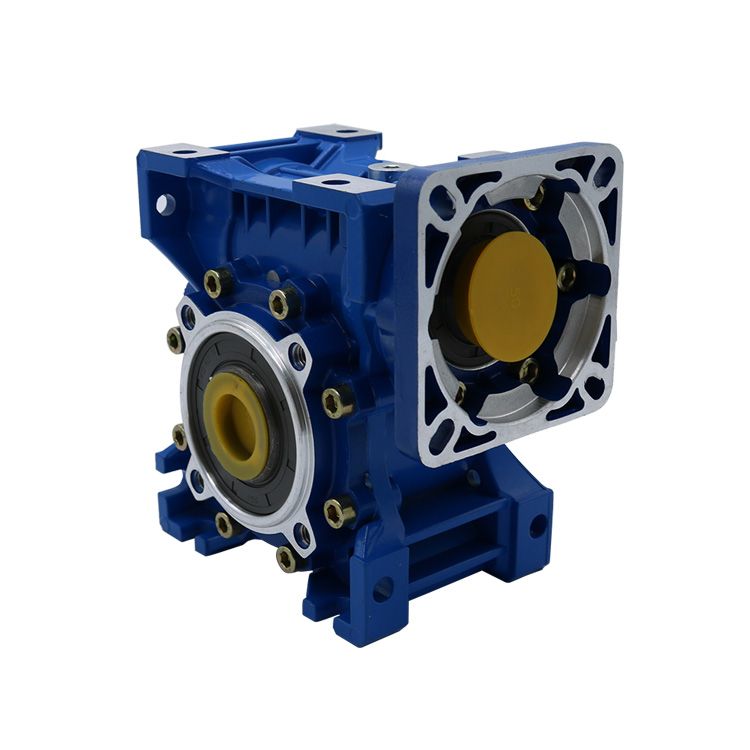

NMRV NRV SERIES WORM GEAR SPEED REDUCER

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

|

NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 |

||||||

|

NMRV |

Worm geared motor |

|||||

|

NRV |

Worm reduction unit |

|||||

|

063 |

center dictance |

|||||

|

30 |

Reduction ratio |

|||||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|||

|

AS |

Single output shaft |

AB |

Double output shaft |

|||

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|||

|

0.75KW |

Electric motor power |

B3 |

Mounting position |

|||

PRECISION BEVEL GEAR

worm and gear: The gears are made of 10-1 tin bronze (with high strength, corrosion resistance and excellent casting properties).

Worm adopts 20CR:carburized alloy structural steel (with high strength, hardenability, wear resistance).

High Speed Bearings and SKF Seals:Use synthetic oil (friction agent: reduce temperature rise, reduce friction).

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Output Flange Mounting Dimensions

NMRV NRV SERIES WORM GEAR SPEED REDUCER FEATURES:

● The weight of the NMRV reducer is relatively light. The shell is made of aluminium alloy. It has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long service life, no noise and so on. It is easy to connect with the motor.

● NMRV reducer is a more practical transmission equipment, and in the appearance design and its integration are more in line with the needs of the public than other types of reducers.

●The application field and popularity of the RV reducer made of aluminium alloy are even better than other types of reducer. It is a kind of reducer with high practicability, and also a combination of advanced technology at home and abroad.

● NMRV reducer is very convenient to connect with ordinary motor, CVT, flange electromagnetic clutch brake unit, and does not need coupling. Suitable for all-round installation, and the output torque It is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement. is relatively large, work fairly smoothly and so on.

Our Company

Zhejiang provice EPT – one of the Biggest Transmission manufactrer in China GEAR TECHNOLOGY CO., LTD

Our company is located in the city of HangZhou ( Beautiful city where West lake located ) , Zhejiang provice Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

NMRV NRV worm gear speed reducer.

It is widely used in many fields such as metallurgy, mine, printing, chemical industry, textile, foodstuff, medicine, rubber and plastic,etc.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or amanufacturer?

A: We are a manufacturer in Zhejiang provice Province, China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply as soon as possible, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Best China manufacturer & factory factory manufacturer for High precision grinding stainless steel gear straight tooth rack and pinion gear With high quality best price

EPG was awarded with “famous product of Zhejiang Province” and “famous brand of Zhejiang Province”.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Application:

-

Mechanical Equipment

- Surface treatment:

-

Polishing

- Processing:

-

Turning

- Tolerance:

-

Customer’s Drawing Request

- Heat treatment:

-

High Frequency Induction Hardening

- Certificate:

-

ISO9001:2009/TS 16949

- Service:

-

24 Hours Online

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging,wooden boxes for outer box or according to customer demand

- Port

- shanghai Port/NinIt must be fixed on a flat surface to avoid either vibrations or tensions nonwishedgbo Port

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 The PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HP

>1000 Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

large made in china diameter precision customized c45 steel herringbone gear

EPG is a specialist manufacturer and exporter that is worried with the layout, growth and production.

Overview

Rapid Details

- Shape:

-

Other, Other

- Regular or Nonstandard:

-

Nonstandard

- Tooth Profile:

-

Helical Gear

- Materials:

-

Metal

- Processing:

-

Hobbing

- Stress Angle:

-

Customer’s Necessity

- Place of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Merchandise Title:

-

c45 metal herringbone equipment

- Heat Therapy:

-

Q&T

- Surface area therapy:

-

Grinding

- Software:

-

Sector/Gearbox/ Transmission

- Regular:

-

GB AGMA ISI DIN JIS

- Blank:

-

Forging

- Good quality handle:

-

UT,MT

- Certificate:

-

ISO9001:2008

Source Capacity

- Provide Capacity:

- a hundred Ton/Tons for each Thirty day period steel herringbone equipment

Packaging & Delivery

- Packaging Specifics

- Package deal adapting to ocean transport

- Port

- Qingdao, shanghai

- Picture Example:

-

Lead Time

: -

Amount(Kilograms) 1 – 30 >30 Est. Time(days) thirty To be negotiated

Online Customization

Video clip Description

Why pick us

We provide one particular-cease service from uncooked Skilled engineer crew to guarantee High precision CNC processing

material business to processing the good high quality. tools.

production and assmbly.

Item Description

large diameter precision personalized c45 metal herringbone gear

The herringbone gears are a variation of double helical gears with obtaining both right and still left hand element that is in a position to cancel thrust or side load on the bearings. The slicing of these gears are accomplished using unique reducing devices that suitably minimize from equally sides at identical time. The helical grooves of herringbone gears seems like V condition when considered from top. These gears are a little bit high-priced in comparison with other gears, as these necessary particular shaping and slicing instruments.

Application

Tailored herringbone gears are extensively utilised in mining sector,cement market, metallurgical market,design components market,nonferrous business, chemical business,port market,and many others.

Relevant Goods

Principal Tools

Technology Procedure

About us

EPG is mainly engaged in the developing and manufacturing of big machinery factors and non-standard equipment parts in accordance to customer’s ask for, including shafts, gears, sprockets, mining equipment areas, weldings, bearings, castings and forgings etc.

The products are primarily utilized in the fields of mining, petroleum, cement, metal mill, electricity plant, sugar factory and many others.

Certificate

FAQ

1. What is your terms of delivery?

A: FOB, CFR, CIF.

2. Can you generate in accordance to the samples?

A: Sure, we can create by your samples or complex drawings. We can construct the molds and fixtures.

3. Do you take a look at all your goods prior to delivery?

A: Of course, we have 100% test prior to shipping