Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CZPT requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

Exploring the Use of Elastomeric Materials in Flexible Shaft Couplings

Elastomeric materials play a crucial role in the design and function of flexible shaft couplings. These materials, commonly known as elastomers, are rubber-like substances that exhibit high elasticity and flexibility. They are widely used in various types of flexible couplings due to their unique properties and benefits:

1. Damping and Vibration Absorption:

Elastomeric materials have excellent damping characteristics, meaning they can absorb and dissipate vibrations and shocks. This property is particularly useful in applications where vibration control is essential to protect sensitive equipment and improve overall system performance.

2. Misalignment Compensation:

Flexible shaft couplings with elastomeric elements can accommodate different types of misalignments, including angular, parallel, and radial misalignments. The elasticity of the material allows for limited movement between the shafts while still transmitting torque efficiently.

3. Torsional Flexibility:

Elastomers offer torsional flexibility, which allows them to twist and deform under torque loads. This feature helps to minimize torsional stresses and torsional backlash, making them suitable for applications requiring precise motion control.

4. Shock and Impact Resistance:

Due to their high resilience, elastomers can withstand sudden shocks and impacts without permanent deformation. This property makes them ideal for use in machinery subjected to varying loads or rapid changes in torque.

5. No Lubrication Requirement:

Elastomeric couplings are often maintenance-free because the elastomer material does not require additional lubrication. This reduces maintenance costs and simplifies the overall system upkeep.

6. Electric Isolation:

In certain applications, elastomeric materials can provide electrical isolation between the driving and driven components. This can help prevent the transmission of electrical currents or static charges through the coupling.

7. Corrosion Resistance:

Many elastomers used in couplings are resistant to corrosion, making them suitable for use in challenging environments where exposure to chemicals or moisture is a concern.

8. Easy Installation:

Elastomeric couplings are often designed for ease of installation and replacement. Their flexibility allows for simple and quick assembly onto the shafts without the need for special tools or complex procedures.

Given these advantages, elastomeric materials are popular choices for various flexible shaft couplings, including jaw couplings, tire couplings, and spider couplings. However, it is essential to select the right elastomer material based on the specific application requirements, such as temperature range, chemical compatibility, and torque capacity.

“`

Explaining the Concept of Backlash and How It Affects Shaft Coupling Performance

Backlash is the angular movement or play between the mating components of a mechanical system when the direction of motion is reversed. In the context of shaft couplings, backlash refers to the free rotational movement between the connected shafts before the coupling transmits torque from one shaft to the other.

Backlash occurs in certain coupling designs that have features allowing relative movement between the coupling’s mating parts. Common coupling types that may exhibit some degree of backlash include elastomeric couplings (such as jaw couplings), gear couplings, and Oldham couplings.

How Backlash Affects Shaft Coupling Performance:

1. Loss of Precision: In applications requiring precise motion control, backlash can lead to inaccuracies and reduced positional accuracy. For example, in CNC machines or robotics, any rotational play due to backlash can result in positioning errors and decreased machining or movement precision.

2. Reversal Impact: When a reversing load is applied to a coupling, the presence of backlash can lead to a brief period of rotational play before the coupling re-engages, causing a momentary jolt or impact. This impact can lead to increased stress on the coupling and connected components, potentially reducing their lifespan.

3. Dynamic Response: Backlash can affect the dynamic response of the mechanical system. In systems requiring rapid acceleration or deceleration, the initial play due to backlash may create a delay in torque transmission, affecting the system’s responsiveness.

4. Noise and Vibration: Backlash can cause noise and vibration in the system, leading to increased wear and potential fatigue failure of components.

5. Misalignment Compensation: In some flexible coupling designs, a certain amount of backlash is intentionally incorporated to allow for misalignment compensation. While this is a beneficial feature, excessive backlash can compromise the coupling’s performance.

Minimizing Backlash:

Manufacturers often design couplings with specific features to minimize backlash. For instance, some gear couplings employ crowned gear teeth to reduce clearance, while elastomeric couplings may have preloaded elastomeric elements. Precision couplings like zero-backlash or torsionally rigid couplings are engineered to eliminate or minimize backlash for applications requiring high accuracy and responsiveness.

When selecting a coupling, it’s essential to consider the application’s specific requirements regarding precision, speed, reversing loads, and misalignment compensation, as these factors will determine the acceptable level of backlash for optimal performance.

“`

What is a Shaft Coupling and Its Role in Mechanical Power Transmission?

A shaft coupling is a mechanical device used to connect two shafts together at their ends, allowing for the transmission of mechanical power from one shaft to another. It serves as an essential component in various machinery and industrial applications where rotational motion needs to be transmitted between two shafts that are not perfectly aligned or are separated by a distance.

The role of a shaft coupling in mechanical power transmission includes the following:

1. Power Transmission:

The primary function of a shaft coupling is to transmit power from a driving shaft to a driven shaft. When the driving shaft rotates, the coupling transfers the rotational motion to the driven shaft, enabling the driven equipment to perform its intended function.

2. Misalignment Compensation:

In real-world applications, it is often challenging to achieve perfect alignment between two shafts due to manufacturing tolerances or dynamic conditions. Shaft couplings are designed to accommodate different types of misalignment, such as angular, parallel, and axial misalignment, allowing the equipment to function smoothly even when the shafts are not perfectly aligned.

3. Vibration Damping:

Shaft couplings can help dampen vibrations and shocks caused by uneven loads or sudden changes in the operating conditions. This vibration damping feature protects the connected components from damage and contributes to the overall system’s reliability.

4. Overload Protection:

In some cases, a shaft coupling can act as a safety device by providing overload protection. When the connected machinery experiences excessive torque or shock loads, certain types of couplings can disengage or shear to prevent damage to the equipment.

5. Torque and Speed Conversion:

Shaft couplings can be designed to provide torque and speed conversion between the driving and driven shafts. This allows for adaptation to different operating conditions and varying torque requirements in the connected machinery.

6. Flexible Connection:

Shaft couplings with flexible elements, such as elastomeric inserts or flexible discs, provide a flexible connection that can absorb shocks and misalignments. This flexibility helps reduce stress on the connected equipment and extends its lifespan.

Overall, shaft couplings are essential components in mechanical power transmission systems, enabling the efficient transfer of rotational motion between shafts while accommodating misalignments and providing protection against overloads and vibrations. The selection of the appropriate coupling type and design depends on the specific requirements of the application, including the type of misalignment, torque capacity, and operating conditions.

“`

editor by CX 2023-09-04

China wholesaler Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CZPT requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

Common Industries and Use Cases for Rigid Shaft Couplings

Rigid shaft couplings find applications in various industries where precise and torque-resistant shaft connections are required. Some of the common industries that use rigid shaft couplings include:

- Manufacturing: Rigid shaft couplings are widely used in manufacturing machinery, such as lathes, milling machines, and CNC equipment, to provide rigid and accurate power transmission.

- Robotics: Robots and robotic arms often use rigid shaft couplings to ensure precise motion and synchronization between motors and actuators.

- Aerospace: In aerospace applications, rigid couplings are used in aircraft engines, landing gear systems, and control surfaces.

- Automotive: Rigid couplings are utilized in automotive powertrains and drivetrains to transmit torque efficiently and withstand high loads.

- Marine: Marine propulsion systems and shipboard equipment often employ rigid shaft couplings for reliable torque transmission in challenging environments.

- Packaging: Packaging machinery relies on rigid couplings to achieve accurate and synchronized movements in filling, sealing, and labeling operations.

- Steel and Metal Processing: Rigid shaft couplings are essential in steel mills and metal processing equipment to handle heavy loads and maintain precision.

- Printing and Paper: Printing presses and paper handling machinery use rigid couplings to ensure precise registration and consistent operation.

- Mining and Construction: Mining equipment and construction machinery utilize rigid couplings for robust power transmission in harsh environments.

- Energy and Utilities: In power generation plants and utilities, rigid couplings are employed in pumps, compressors, and turbines.

Rigid shaft couplings are versatile and can be found in numerous other industries where precise and efficient power transmission is critical for smooth operation and high-performance machinery.

Are there any safety considerations when using rigid shaft couplings in critical applications?

Yes, when using rigid shaft couplings in critical applications, several safety considerations should be taken into account:

- Torsional Stiffness: Rigid couplings have high torsional stiffness, which can lead to increased stresses and potential failures in the connected equipment. Proper analysis of torsional vibrations and stiffness compatibility with the connected components is crucial.

- Shaft Alignment: Inaccurate shaft alignment can lead to additional loads on the coupling and connected machinery. Precision alignment is essential to prevent premature wear, increased stress, and potential breakdowns.

- Overloading: Exceeding the rated torque capacity of the coupling can result in sudden failures and damage to machinery. It’s essential to operate within the coupling’s specified limits to ensure safe operation.

- Maintenance: Regular inspection and maintenance are critical to identify signs of wear, fatigue, or misalignment. Neglecting maintenance can lead to unexpected failures and safety hazards.

- Environmental Factors: Harsh environments, extreme temperatures, and corrosive substances can impact the integrity of rigid couplings. Choosing appropriate materials and protective measures can mitigate these effects.

For critical applications, it’s recommended to work closely with experienced engineers, perform thorough risk assessments, and follow industry standards and best practices to ensure the safe and reliable use of rigid shaft couplings.

What are the Materials Commonly Used to Manufacture Rigid Shaft Couplings, and How Do They Impact Performance?

Rigid shaft couplings are typically made from a variety of materials, and the choice of material can significantly impact the performance of the coupling in specific applications. Some common materials used in manufacturing rigid shaft couplings include:

- Steel: Steel is one of the most commonly used materials for rigid shaft couplings. It offers excellent strength and durability, making it suitable for high-torque and heavy-duty applications. Steel couplings can withstand significant stresses and provide reliable torque transmission.

- Stainless Steel: Stainless steel couplings offer the same benefits as regular steel couplings but with the added advantage of corrosion resistance. They are commonly used in applications where the coupling may be exposed to harsh environments or moisture.

- Aluminum: Aluminum couplings are lightweight and have good corrosion resistance. They are often used in applications where weight reduction is essential, such as in aerospace and automotive industries.

- Brass: Brass couplings are known for their excellent machinability and corrosion resistance. They are commonly used in applications where electrical conductivity is required.

- Cast Iron: Cast iron couplings are robust and offer good resistance to wear and tear. They are commonly used in industrial machinery and equipment.

The choice of material depends on various factors, including the application’s operating conditions, such as torque requirements, temperature, and environmental conditions. For example, in high-torque applications, steel or stainless steel couplings are often preferred due to their high strength. On the other hand, aluminum couplings are favored in applications where weight reduction is critical.

It is essential to consider the specific needs of the application and the coupling’s material properties to ensure optimal performance, longevity, and reliability of the rigid shaft coupling.

editor by CX 2023-08-22

in Zagreb Croatia sales price shop near me near me shop factory supplier Excavator Bearing Gear Crank Shaft for Travel Motor 30t manufacturer best Cost Custom Cheap wholesaler

Owing to our sincerity in giving very best service to our clientele, comprehending of your demands and overriding sense of obligation toward filling ordering specifications, The group has taken portion in the producing and revising of ISO/TC100 worldwide chain regular a number of several years in achievement and hosted the 16th ISO/TC100 Global once-a-year assembly in 2004. We offer OEM support. Solution Description

EPTTXiHu (West EPT) Dis.ng EPT EPT Custom made Spline Shaft

The shaft is a kind of mechanical EPTT, which transmits mechanical torque. There is a EPTTitudinal keyway on the outer surface area of the shaft, and the rotating member sleeved on the shaft also has a corresponding keyway, which can hold rotating synchronously with the shaft. While rotating, some can also slide EPTTitudinally on the shaft, this kind of as EPTT shifting EPTs.

We can make customers’ satisfactory products according to the samples or drawings supplied by consumers. For the completion of a item, we also require to know its materials, warmth treatment method specifications and surface area remedy specifications. We are a manufacturing facility with forty many years of production knowledge, welcome to seek the advice of.

The edge of our shaft

one EPT carrying potential

2 Excellent orientation

3 Tiny stress focus

4 Convenient processing, substantial precision with grinding approach

five EPT toughness and EPTT lifestyle

EPTTngyin EPTTXiHu (West EPT) Dis.ng EPTTry EPT EPTT, Ltd. is a EPTTized supplier of a complete range of motor shafts, EPTs, Flanges(Couplings), EPT racks, sprockets, pulley, EPTTd elements and so on.

Owing to our sincerity in offering best services to our clients, understXiHu (West EPT) Dis.Hu (West EPT) Dis. of your demands and overriding sense of obligation towards filling purchasing demands, we have obtained the EPTT of buyers throughout the world. Having accrued treasured expertise in cooperating with foreign clients, our items are offering effectively in the American, European, South American and Asian markets.Our goods are created by modern computerized EPTTry and tools. In the meantime, our products are manufactured in accordance to high quality stXiHu (West EPT) Dis.Hu (West EPT) Dis.rds, and complying with the global EPTd stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd conditions.

With several years’ encounter in this line, we will be EPTTed by our benefits in aggressive cost, 1-time delivery, prompt reaction, on-hand engineering assist and very good after-sales services.

Furthermore, we also can design and make non-stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd goods to meet up with customers’ EPTT requirements. EPTT and credit rating are the bases that make a company alive. We will provide greatest solutions and substantial quality items with all sincerity. If you want any info or samples, please make contact with us and you will have our quickly reply.

FAQ

one)Are you investing organization or producer?

We are manufacturing unit.

2)How can I customize my products?

Connect your drawing with particulars(floor treatment,substance,quantity and EPTT needs etc.)

three)How EPTT can I get the quotation?

We will give you the quotation inside forty eight several hours(contemplating the time difference)

4)How EPTT will you create the parts?

EPTTly it is five-ten daEPTTif the goods are in inventory. Or it is fifteen-25 daEPTTif the goods are not in inventory, it’s according to amount.

5)Do you provide samples? Is it free or additional?

Of course, we could supply the sample, the samples and delivery EPTs want to be borne by the shopper.

six)What is your conditions of payment?

Payment le1000 USD, one hundred% in EPT. Payment ge1000 USD, 30% T/T in EPT, stability just before cargo. If you have any questions, please don’t hesitate to get in touch with us.

7)What if the goods we EPTd are not great?

Make contact with us without having hesitation, our EPTT right after-sales provider will get the duty.

Best best made in China – replacement parts – PTO shaft manufacturer & factory Bkm063 garden tractor pto shaft Gearbox Worm Reduction Gear Motor Geared Transmission High Speed Reducer Helical Hypoid Manufacture Pto Planetary Electric Vehicle Iron Double Auto with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

baler pto shaft EPG tom woods 1350 jk Equipment international 1086 pto shaft removal is bush hog pto shaft lock pin situated 2007 jeep liberty front generate shaft in pto shafts at rural king XiHu bush hog pto clutch Spot bondioli & pavesi pto areas HangZhou dana driveshaft Zhejiang pto shaft protection chain ,China. It is 30km from our factory to HangZhou global airport.

BKM063 Gearbox worm reduction gear motor geared transmission higher speed reducer helical hypoid manufacture PTO planetary electric powered car iron double vehicle

Solution Traits

1. Push by hypoid gear, has massive ratios.

two. Massive in output torque, high performance, energy preserving and environmental safety.

three. Created of higher quality aluminum alloy, mild in weight and non-rusting

four. Sleek in running and reduced in sounds, can perform extended in dreadful problems.

5. Great-seeking in physical appearance, sturdy in provider existence and modest in volume.

6. Ideal for all spherical set up, extensive application and simple of use.

seven. The Mounting Dimension of BKM sequence are suitable with NMRV collection worm equipment device (A element of NMRV050 dimensions are various from BKM050)

8. Modular and multi-framework can meet up with the requires of various situations.

| TYPE | BKM50,BKM63,BKM75,BKM90,BKM110 |

| Transmission Stage | B: 2 stages |

| C: 3 levels | |

| Ratio | B: 7.5,10,12.5,15,20,25,thirty,forty,50,60 |

| C: fifty,60,seventy five,one hundred,125,a hundred and fifty,200,250,three hundred | |

| Output torque | Up to 500N.m |

| Motor electricity | 0.12~5.5KW,with flange:B5 or B14 |

| Housing content | Aluminum alloy |

| Output shaft | material: 40Cr |

| Hardness degree: 242-286HB | |

| Helical gear | Material:20CrMnTi |

| Hardness amount: fifty eight-62HRC | |

| Precision level:6 grade | |

| Transmission performance | B:ninety two%-94% |

| C:ninety%-ninety two% | |

| Oil seal brand | SKF |

| Bearing | C&U |

| Lubricant | Mineral oil or artificial oil |

our firm

Best China manufacturer & factory SMR Shaft Mounted worm gear motor reducer With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

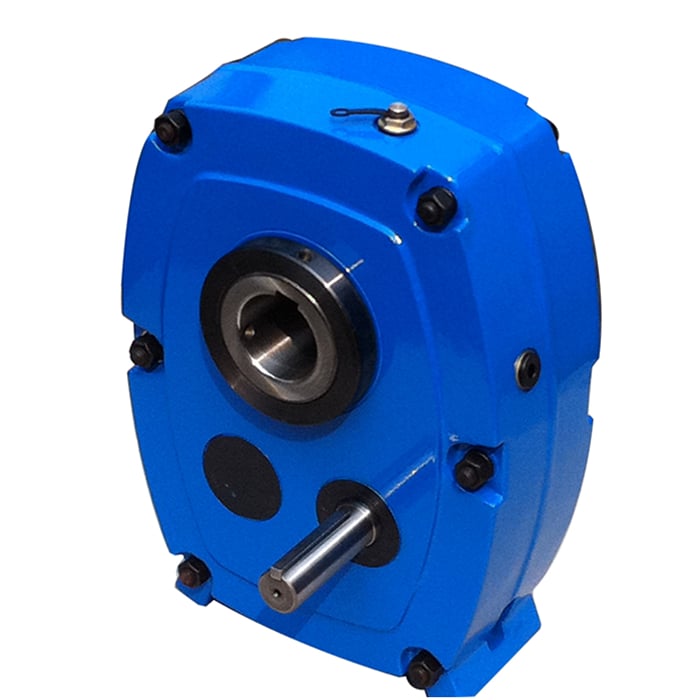

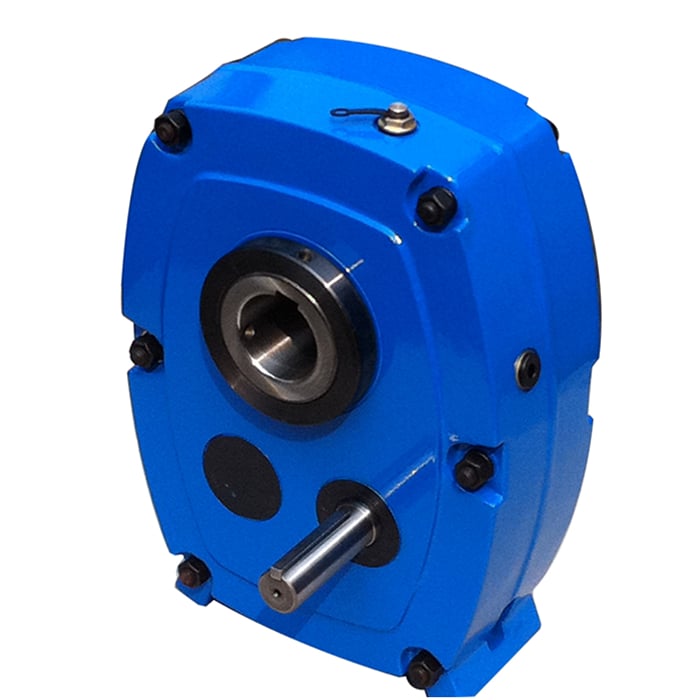

Overview

In addition to our two sales offices in the US, EPG employs a nationwide network of sales partners who will provide expert technical support to your company.

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

max 8000NM

- Input Speed:

-

1440

- Output Speed:

-

72, 110, 288

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

SMR

- Rated Power:

-

2.68~134.2

- color of Shaft Mounted speed reducer:

-

green blue gray

Supply Ability

- Supply Ability:

- 500 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- standard export packing and wood pallets packing

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Quantity(Boxes) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

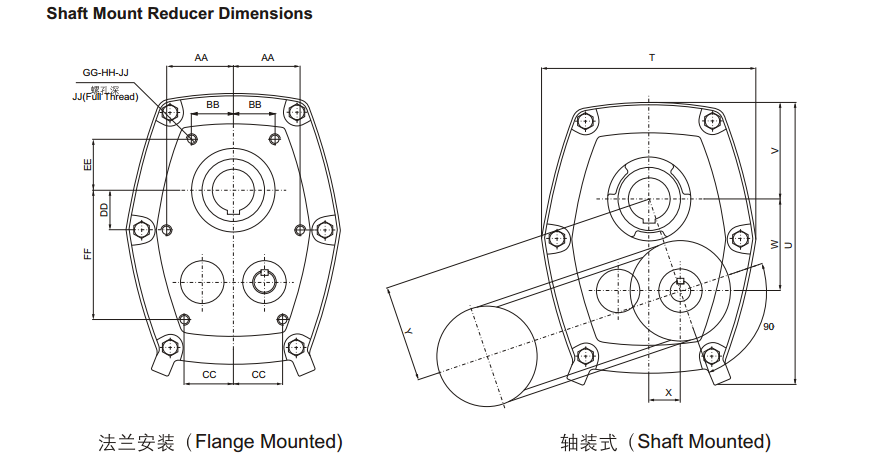

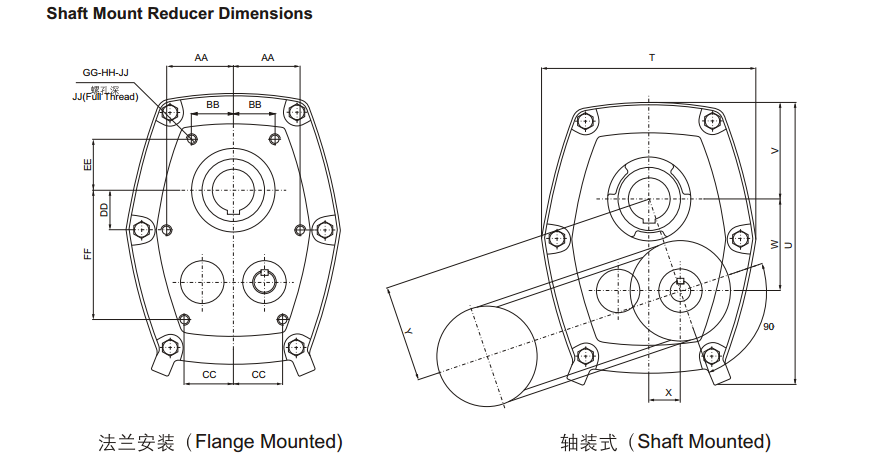

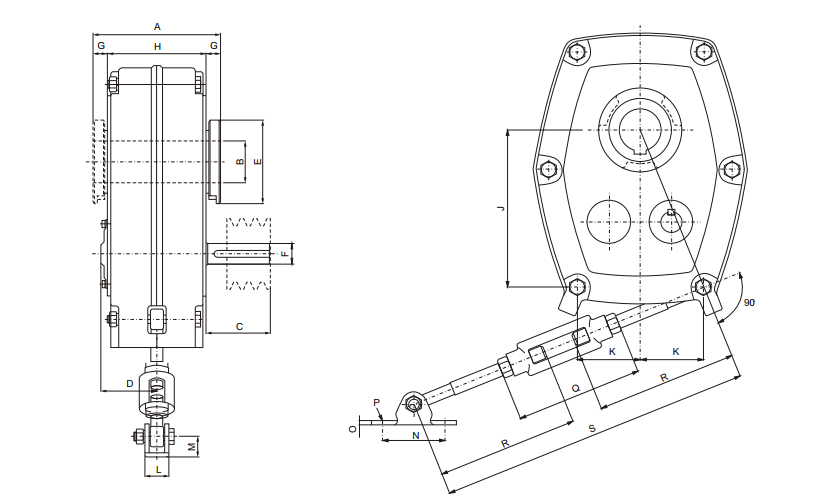

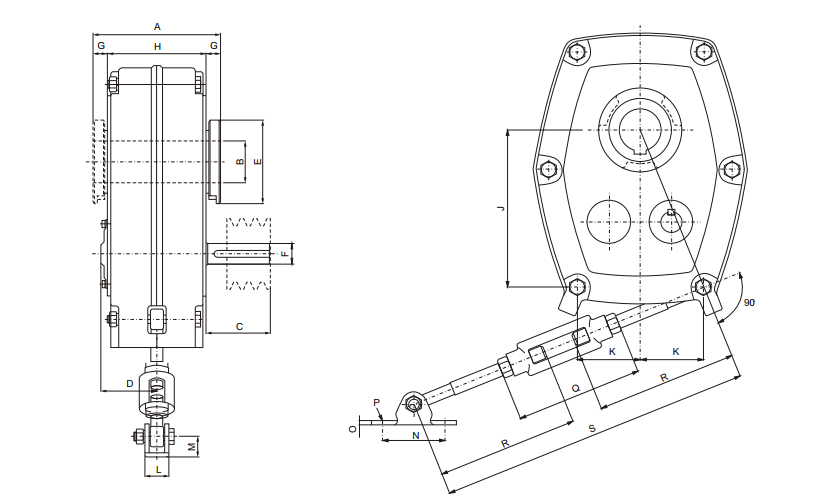

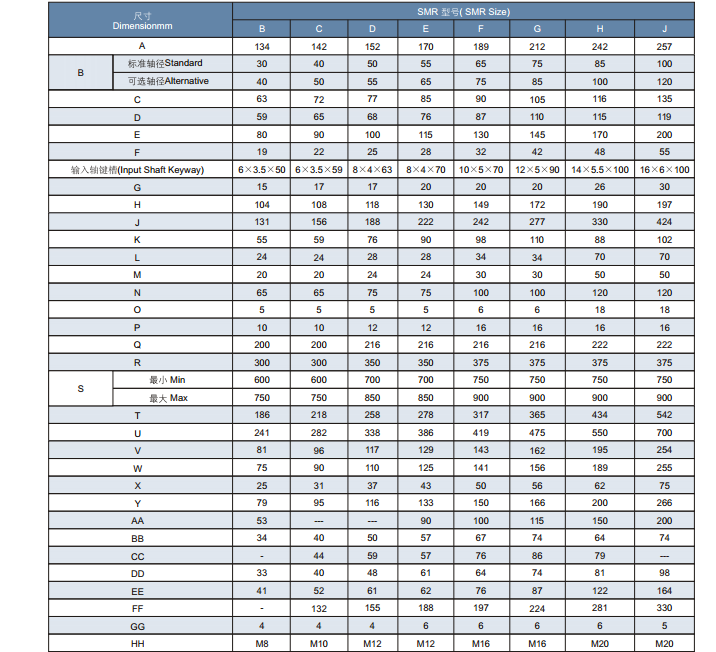

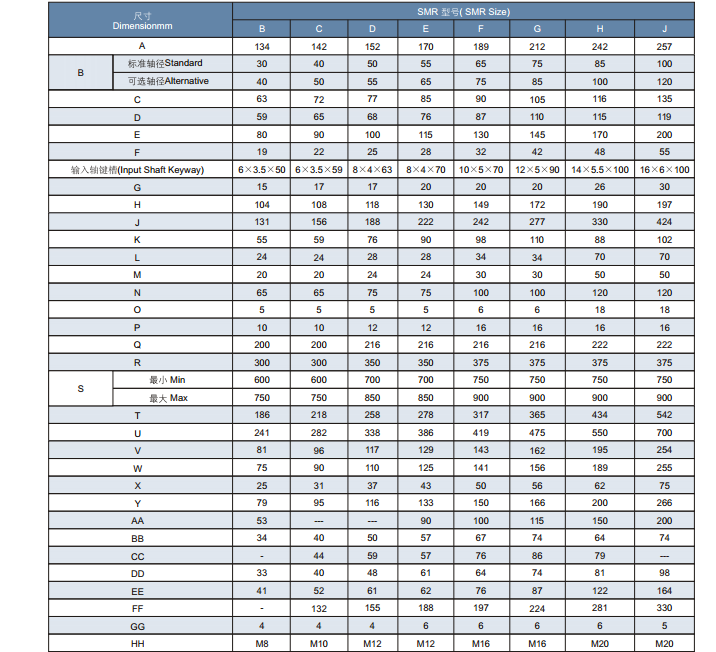

Product Description

SMR Shaft Mounted worm gear motor reducer

1. Precision High Quality Gearing

Computer designed helical gears, strong alloy materials for high load capacity, ground profile (some intermediate pinions are shaved). Crown tooth profile, in conformance with ISO 1328-1997, 98% efficiency for per stage, smooth quiet operation with several teeth in mesh.

2. Output Hub

*Standard or alternative output hole diameter for choice as follow.

|

ITEM |

Standard output hole diameter |

Alternative output hole ø |

|

B5 |

ø30 |

ø25/35/40 |

|

B13/20 |

ø30 |

ø25/35/40 |

|

C5 |

ø40 |

ø35/45/50 |

|

C13/20 |

ø40 |

ø35/45/50 |

|

D5 |

ø50 |

ø45/55/60/65 |

|

D13/20 |

ø50 |

ø45/55/60/65 |

|

E5 |

ø55 |

ø50/60/65 |

|

E13/20 |

ø55 |

ø50/60/65 |

|

F5 |

ø65 |

ø60/70/75 |

|

F13/20 |

ø65 |

ø60/70/75 |

|

G5 |

ø75 |

ø70/80/85 |

|

G13/20 |

ø75 |

ø70/80/85 |

|

H5 |

ø85 |

ø80/90/95/100 |

|

H13/20 |

ø85 |

ø80/90/95/100 |

|

J5 |

ø100 |

ø90/95/105/110/105120 |

|

J13/20 |

ø100 |

ø90/95/105/110/105120 |

3. Strong Alloy Steel Shafts

Strong alloy steel, hardened, ground on journals, gear seatings and extensions, for maximum torsional loads. Generous size shaft keys for shock loading and conform to ISO standards.

4, Back Stops

Alternative parts, anti-run back device, are available on all 13:1 and 20:1. Ratio units and do not recommend for 5:1.

5. TorMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.que Arm Assembly

For easy adjustment of the belt.

Detailed Images

Related Products

Certifications

Packing & Delivery

Packing Images of SMR Shaft Mounted worm gear motor reducer

Inner Packing: PP bag with carton;

Outer Packing: Wooden case;

Shipment: 20-30 days upon receiving the deposit.

About Us

About Hangzhou Ever-power group(HZPT):

Q: Are you trading company or manufacturer ?

A: HZPT group consists in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 30-45 days. The time may vary depending on the product and the level of customization. For standard products,

the payment is: 30% T/T in advance ,balance before shippment.,for customized products,50% downpayment is requested normally.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with detail size, material and further specifications;when you place orders,pleasure contact us in advance to communicate all details

Hollow made in china shaft compact types ac worm drive servo small gear reduction variator variable speed electric motor

Our merchandise range also addresses locking assemblies (clamping factors/locking system), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, common joint, rod finishes and yokes.

Overview

Quick Particulars

- Relevant Industries:

-

Numerous equipment and petrochemical industries

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

one.5~118Nm

- Input Velocity:

-

1400/min

- Output Speed:

-

880~one thousand/min

- Manufacturer Identify:

-

OEM

- Solution name:

-

tiny equipment reduction variator variable velocity electrical motor

- Software:

-

Meals Stuff, Ceramics, Chemical, Packing, Dyeing, Wooden working, Glass.

- Shade:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

one.4~seven

- Warranty:

-

1 Calendar year

Source Capability

- Provide Potential:

- 36000 Piece/Pieces per Thirty day period

Packaging & Delivery

- Packaging Information

- Clear box packaging, or colour box packaging, it also can be personalized.

- Port

- Ningbo/Shanghai

On the web Customization

Hollow shaft compact sorts ac worm drive servo modest equipment reduction variator variable speed electric motor

Q1.How to choose a variable speed electrical motor which fulfills our prerequisite?

A1: You can refer to our catalogue to decide on the gearbox or we can assist to pick when you supply

the specialized data of output torque, output velocity and motor parameter and so on.

Q2.How is your price tag? Can you provide any price reduction?

A2: We will give the greatest cost we can foundation on your wants and the portions.

Q3.Do you provide any browsing?

A3: Indeed! We sincerely invite you to check out us! We can choose you from airport, railway station and so on.

Also, we can set up housing for you. You should permit us know in innovative.

Q4.When is the ideal time to contact you?

A4: You can contact us by electronic mail any time, we will reply you as before long as achievable.

Q5.How prolonged will it get for the direct time?

A5: For our common model, please refer to the different item web pages to check out the direct time.

For the OEM/ODM goods, remember to make contact with us for additional info.